Emergency Response Management Offshore Safety

Oil rig safety - Lessons from Deepwater Horizon

Based on the aftermath investigation of the sinking of Deepwater Horizon, several weaknesses of the oil rig emergency response management were discovered, despite regular inspections in compliance with SOLAS and USCG requirements, citing an "outstanding safety culture" on board.

Deepwater Horizon was an ultra-deepwater, semi-submersible offshore drilling rig owned by Transocean. On April 20, 2010, while drilling at the Macondo Prospect in the Gulf of Mexico, a blowout of methane gas caused a detonation on the platform that killed 11 crew members and ignited a fireball. An attempt to activate the blowout preventer failed as the blind shear ram to plug the well. The fire was out of control, and two days later, on April 22, the Deepwater Horizon sank, leaving the well open at the seabed. The resultant oil spill persisted until July 15, when it was closed by a cap. The US authorities established the Gulf Spill Restoration project to restore much of the coastline.

Why should you record your (offshore emergency) practice?

Imagine a team practice session. You get a task as a team in different areas of the offshore installation and execute. After half an hour, the training is called. You did not bad, but it could be better. Next week, same time... and the results are almost the same. You start thinking and analyzing, but it is difficult to be aware of everything of what you did, even you do while practicing.

Whatever technology you use for recording your drills, you should have a concept of improvement ready first. There are big benefits in recording your training sessions and reviewing them at a later moment - building awareness on your performance, identifying strengths and mistakes and ensure that you practice where improvement potential for your emergency response exists.

7 Practical Steps to Improve Safety & Human Reliability

Jake Mazulewicz will discuss the framework to safety in hazardous industries like offshore installations. He will address the big question: "How can we effectively balance error-prone human nature with increasingly complex, expensive and hazardous environments?"

Jake presents seven practical steps to improve safety and human reliability.

A fantastic, very interesting webinar on human nature and the way organizations can deal with mishaps.

Norway’s HSE Offshore Standards

With a long history and tradition in travelling the rough sea and also extreme weather conditions under their belts, Norwegians have excelled in learning how to stay safe. This is one of the reasons, why today Norway is a highly respected and leading nation in regards of emergency response management technology for offshore applications.

In 1978, the government launched an extensive offshore safety programme, after an incident on the Ekofisk complex the year before. Despite the new government initiative, Norway experienced its worst industrial disaster two years later when the Alexander Kielland accommodation rig capsized. 123 people died. Emergency response management had to be drastically improved.

Offshore safety: How to improve your operations cost-effectively

Safety hazards in the offshore industry may be more prevalent than in any other work environment. However, proactive measures safeguard crew and productive operations. Although your goal is to make as much profit as possible, this shouldn't be at your health and safety expense. With this peace of mind, offshore safety is possible without hurting your productivity. Digital technologies such as wearables and collision avoiding systems can help you achieve both in a big way.

Despite safety being a top priority in the offshore industry, operations and profits are legitimate targets. Therefore, boosting safety and productivity needs to be a top priority. Consequently, governmental bodies implement installations' safety standards and emergency response management to try and reduce the hazards and risks while stepping up productivity in offshore oil & gas exploration.

Emergency Response: Electronic Mustering

Floating Production Storage and Offloading (FPSO) vessels and drillships operate in some of the most challenging environments on Earth. One of the critical components of emergency preparedness is effective mustering, where crew members are accounted for at designated assembly areas. With the introduction of electronic mustering, this procedure has significantly changed and improved. In this article, we will describe, in detail, the importance of emergency response on FPSOs and provide a step-by-step guide on running electronic mustering drills.

Emergency Response: How to maintain a safety record on wind farm ships

Wind farm ships, also referred to as SOVs, CSOVs, installation vessels or jack-up barges, are vital components in every single stage of life of offshore wind farms. These specially designed boats are essential for crew transportation, building, maintaining, and decommissioning wind turbines in some of the harshest ocean conditions. As the world's need for renewable energy keeps increasing, ensuring the safety of both the wind farm ships and their crew members becomes even more critical nowadays.

Operating on the highest level of efficiency and security for the vessels themselves and their crew while maintaining an excellent safety record in offshore daily duties is one of the most significant factors we will discuss in this article.

Emergency Response: EHS Risk Assessment

The offshore sector, characterised by its demanding conditions, encounters various risks related to the well-being of the crew, structures and nature. In this context, a comprehensive assessment focusing on Health, Safety, and Environment (HSE) or Environment, Health, and Safety (EHS) is essential for an appropriate emergency response and prevention. It goes beyond merely fulfilling legal obligations; it's vital for maintaining operational safety and safeguarding the environment. Such evaluations are crucial in spotting possible dangers, assessing the associated risks, and establishing robust strategies to reduce these risks.

Offshore Wind Energy Safety Jobs

A new report by the Offshore Wind Industry Council (OWIC) shows a significant increase in jobs in the offshore wind sector by 2030 – with forecast jobs exceeding 100,000 for the first time, and a dramatic surge of workers required over the next seven years. So, what does it takes to work in the offshore industry?

FPSO Emergency Response Jobs

Hydrocarbons are processed and stored on floating production, storage, and offloading (FPSO) units offshore. These sophisticated, floating industrial complexes with high-tech equipment and systems make it hard for them to do complex offshore production tasks. They're exposed to unpredictable weather and hurricanes because they're located in the sea. A specialised Emergency Response Team is even more important when there are dangerous substances around. Their presence is crucial not just for crew safety but also for protecting the environment. In crises, the ERT has experts trained to act fast and efficiently. So what kind of emergency response team jobs are out there?

Emergency Response Drill

FPSOs, oil rigs or any other offshore protocols. Emergency response drills are a big part of the safety protocols created to prepare crew members for any kind of emergency. Their trained response gives accuracy and efficiency and reduces the time needed to minimize and mitigate risks and prevent incidents, accidents, or any kind of disaster. The execution and value of these drills underscore the industry's commitment to safety and environmental protection, acting as real insurance against potential hazards that could have far-reaching consequences. While reading, we break down the most important aspects of it.

Emergency Response Management: Preparedness

The exploration and production of oil and gas, especially offshore, have become critical to meeting global energy demands, more than ever before. We produce more, we sell more, we need energy for that. Any offshore operation, whether it’s an Oil Rig, FPSO, even an SOV, operating around the wind park, by their very nature, presents some unique challenges including extreme weather conditions, remote locations, and the complex and hazardous nature of the materials being handled. Given these factors, we need to ask ourselves one question. Why emergency preparedness is important and it is not merely an option? It is a vital necessity. This article explores the reasons why, highlighting use cases which shows the significant consequences of both preparedness and lack of it.

Emergency Response Management: Safety Training

The renewable energy sector has been rapidly expanding for the past decade, led by the increased installation of offshore wind farms that contribute to the global energy mix. At the helm, such operations involve complex logistics, cutting-edge technology, and stringent safety measures, meaning that vessels are the lifeline of this activity in regard to moving personnel, equipment, and materials to and from wind farms. Safety remains a high priority onboard wind farm vessels for sea operations, which are often in severe and extremely challenging conditions. This post deeply looks at how safety is executed on these vessels with offshore safety training, safety measures, and the culture of safety that oversees these operations.

Emergency Response Management: Wearable Tech

The offshore oil and gas industry has been on the front line when it comes to adopting new technologies that have been implemented in consideration of safety, efficiency, and productivity. Working under some of the most complex and hazardous environments worldwide, the industry always looks for new developments that might help reduce risks and enhance operational dynamics. Of these many developments, wearable technologies have been one of the most strategic drivers of change in how things get done offshore. This article looks at how wearable technology history has matured over the years in the offshore oil and gas sector, covering subjects not just during the period of inception but also those subjects covering the radical growth and transformation that the technology has gone through.

Emergency Response Management: Safety Training

Wind energy is turning out to be one of the prime movers in the transition toward renewable sources of energy. The wind farm industry is growing rapidly all over the world. As the capacity of this industry increases, so does the demand for skilled professionals able to work safely within this high-altitude, heavy-machinery, highly unpredictable weather environment. Safety is one of the top concerns in the wind farm industry since it actually pertains to saving the lives of those working in the said field and taking care of operational efficiency with regard to turbines and everything that surrounds the structure. This is why highly specific safety training is a must, even before one gets into such a line of work.

Emergency Response Management: FPSO Vessel

The FPSO vessel stands out as indispensable to the offshore oil and gas industries. These complex facilities at sea form the missing link between hydrocarbons extracted from subsea reservoirs and their transportation ashore. The FPSOs have been designed to process and store crude oil and gases with subsequent offloading. Their design enables them to serve in some of the toughest environments on Earth. However, peculiar operational features and intrinsic hazards are imposed with stringent safety considerations to safeguard human life and the environment.

The safety considerations of FPSOs arise from the interaction of several factors, including structural design, operation environment, processing activities, and human factors. This article will discuss the measures for mitigating these risks in further detail to show ways of ensuring the smooth function and efficiency of these vital offshore assets.

emergency response offshore wind farm

Emergencies at sea are challenging under any circumstances, but for Service Operation Vessels (SOVs) working in remote offshore wind farms, particularly in regions like the North Sea, they present unique risks and operational demands. With harsh weather, complex machinery, and limited access to immediate external help, even minor incidents can escalate rapidly. In this article, we discuss how offshore wind farm vessel crews respond to emergencies, the role of mustering, and how digital solutions improve safety and coordination when every second counts.

emergency response and vessel gangway

Offshore energy operations depend on the safe and efficient movement of crew between vessels and installations—an intricate process shaped by engineering, weather, and human precision. From traditional ladders and cranes to advanced motion-compensated gangways, each method defines how offshore teams work and stay safe. In this article, we look into the technologies, procedures, and digital innovations that are transforming personnel transfer and redefining safety standards at sea.

emergency response and North Sea Wind

This blog post explores the North Sea’s transformation from a historic oil and gas powerhouse into a global hub for renewable energy. It traces the rise of offshore wind, examines today’s large-scale wind farm developments, and highlights their economic, environmental, and labour-market impacts. With the Wind Farm North Sea at the centre of Europe’s energy transition, the region illustrates both challenges and opportunities.

Emergency response and Safety Equipment

Offshore energy operations in oil and gas and offshore wind expose personnel to complex and evolving risks that demand rigorous health, safety, and environmental management. From hazardous processes and extreme weather to remote locations and limited evacuation options, safety depends on the effective interaction of people, procedures, and safety equipment offshore. In this post, we discuss why offshore HSE is essential, what safety equipment is used, and how safety procedures and digital assistance solutions protect lives at sea.

Offshore Industry: Better Safety Training Results

The Great Crew Change puts an additional emphasis on strengthening safety and emergency response management on offshore installations in the oil and gas industry.

Safety awareness, skills and continuous training are the recipe to foster standards and to avoid incidents. As all measures require time, resources and attention from corporations and crew, they must be as efficient as possible to enable less operational disturbance, minor financial impact and greater effect on overall safety.

Improve Your Offshore Emergency Response Management

The potential profits of offshore drilling are significant, but so are the risks. Therefore, safety must be the number one priority on these installations. Lives and wealth are at risk and must be secured because you care for the wellbeing of your personnel, and you are responsible for smooth and efficient operation in a risky environment at the same time. One crucial approach to improving your emergency response is preparedness.

According to safeopedia, emergency response management "includes any systematic response to an unexpected or dangerous occurrence." HSE supervisors and managers design emergency response procedures to mitigate the impact of an event on people and the environment.

Offshore safety equipment: Transponders to the rescue!

Safety on offshore installations is a top priority. Safety regulations and standards will keep incidents at bay, but risks persist. In emergency evacuations, processes and equipment are in place to save lives. Transponders help fill a gap in the mustering process, improving your emergency response management substantially.

Working on an offshore installation, floating production site (FPSO), or a wind farm is a hazardous occupation. The environment is harsh, the working conditions stressful, and the shifts long. Personnel stays on board for weeks, sometimes for months. Incidents are common, despite training, best practices and regulations. According to the Bureau of Safety and Environmental Enforcement (US), six workers died in offshore-related accidents in 2020, and 160 were injured.

Lives at stake – is offshore personnel safety good enough?

A holistic HSE philosophy includes all aspects of offshore activity, including the standard of the installations, construction philosophy, operational standards, training of personnel, and maintenance. All of this with one main goal: minimising all forms of incidents and to keep people safe.

Why are companies, in 2021, still using outdated methods to keep track of their personnel offshore? Many companies use pen and paper-based lists to keep a POB overview. How useful would these lists be in case of another “10-year accident”, in the middle of a stormy night, with harsh seas and crew members in panic?

Emergency Response Management: What is e-mustering?

An automated electronic mustering solution is a vital resource to improve emergency response management. It handles many time-consuming tasks emergency managers must address during a crisis. It could be the right choice for companies looking to streamline their emergency response efforts as such e-mustering solutions help to confirm staff are safe, identify and locate personnel still at risk, and simplify drilling so that everyone can get back to normal work faster.

The initial minutes of an emergency are vital. The team must be trained, the organisation prepared, and emergency procedures are known to react fast and coordinated. The first step of developing a proper emergency response is to conduct a risk assessment to identify potential emergency scenarios. Understanding what can happen will enable you to determine resource requirements and develop plans and procedures to prepare your offshore installation, vessel or plant.

Emergency Mustering: How to improve Offshore Safety

Keeping people safe and infrastructure protected is a number one priority for every organisation. Knowing where your staff are can make the difference between life and death in specific situations. During an emergency, it is vital to know who has or has not left the hazardous area. The ability to track multiple people, at speed in a mass evacuation can prevent injuries, fatalities and loss.

Improving your capabilities for emergency response management is vital.

There are many intrinsic weaknesses in manual mustering. The system relies on a small number of trained personnel to undertake the subsequent roll call but also heavily on staff following procedures.

Offshore wind farm safety

Wind farms are becoming increasingly common as a source of renewable energy, so it is important to ensure that they are operated safely and securely. They produce electricity without producing greenhouse gas emissions, making them an important part of efforts to combat climate change. Approaching and leaving wind turbine platforms is one of the critical aspects of wind farm safety. All the movements need to be carefully planned and executed to minimize the risk of worker accidents or injuries.

Emergency Response Management and Communication

Offshore wind farm safety is a top priority for the renewable energy industry. The construction and maintenance of these turbines involve a range of complex and potentially hazardous operations that require careful planning, execution, and ongoing maintenance. In addition, personnel involved is exposed to a range of hazards such as inclement weather conditions, heights, heavy machinery, and electrical equipment. Therefore, all workers and stakeholders must be informed about safety procedures, hazards, and emergency response protocols.

HSE Roles in Wind Farm Operations

Health, Safety, and Environment (HSE) are three of the most critical aspects of any industry, but they become even more vital in offshore wind farm operations. The offshore wind energy industry poses unique challenges that require careful management, including harsh weather conditions, complex machinery, and long distances from shore. As the industry continues to grow, driven by the need for clean energy, HSE's role in offshore wind farm operations becomes increasingly essential.

Emergency Response Kits

Since FPSOs are in the middle of the ocean, often far from help and in rough waters, they must be ready to deal with emergencies to keep people safe, the environment clean, and the operations running smoothly. Working on these ships can be dangerous; they deal with explosive-related things, complicated machinery, and absurd weather high waves and storms, so they need to have solid safety plans. Because these boats are isolated, an emergency can get bad quickly. Having knowledgeable emergency plans ready to go is key; the point of this piece is to break down the must-haves for emergency response kits for FPSO, considering the intense nature of the work they do out there in the ocean. There's a safety kit on those vessels that's ready for everything...fires, medical crises, oil leaks, and crazy storms. These safety kits demonstrate how much oil companies care for the environment, keep things safe, and make sure they can keep working no matter what happens. Let's take a look at what's in them.

Emergency Response Plan

Offshore oil rigs are critical to global energy production but are high-risk environments due to their remote locations and exposure to extreme conditions. The development and implementation of a comprehensive emergency response plan (ERP) are crucial to ensuring the safety of personnel, protecting the environment, and maintaining the structural integrity of the rig. An effective ERP includes detailed risk assessments, scenario planning, crisis communication strategies, evacuation protocols, and environmental emergency responses. These elements work together to prepare for and mitigate the impacts of potential emergencies such as fires, explosions, oil spills, and severe weather. Regular updates and continuous training are important to keep the ERP relevant, ensuring a coordinated and swift response to any emergency that may arise.

Emergency Response and Offshore Rigs

Offshore installations are among the most hazardous workplaces, where extreme conditions and complex operations demand uncompromising safety standards. In such environments, even minor lapses can lead to major incidents. To manage these risks, a strong safety culture and clearly defined protective measures are essential. One critical element is the implementation of red zones—high-risk areas requiring strict access control. In this article, we discuss how red zones function, how to establish them effectively, and the technologies that support their enforcement.

Emergency Response Management and POB

Accurately tracking personnel on Service Operation Vessels is critical for safety, especially in remote offshore environments where emergencies demand swift, informed responses. Traditional manual and swipe card-based systems often fall short under pressure, leading many operators to adopt hands-free RFID-based POB technology. These systems provide real-time visibility without user interaction, ensuring crew are always accounted for. In this article, we discuss the benefits of RFID-based POB solutions and why they are becoming the new safety standard offshore.

Emergency Response Management and FPSO operations

Floating production, storage and offloading (FPSO) units are central to deepwater energy, yet they face complex operational, environmental and safety challenges. From harsh seas and piracy risks to intricate production, storage and offloading processes, risk management and emergency preparedness shape every stage of their lifecycle. Electronic mustering technologies now redefine evacuation readiness. In this article, we discuss the theatres of FPSO operations, their risks, safety frameworks, and the evolving strategies that safeguard crews and assets.

Offshore Windpark HSE

In this whitepaper, we’ll explore the potential of offshore wind power and illustrate some of the dangers associated with working in such an environment, examine the rescue chain and suggest ways to improve it.

Increasing QHSE offshore standards

Reliable products have always been the core of IDENTEC SOLUTIONS’ offering. With our enhanced personnel safety solution Crew Companion we increase emergency response management on a grand scale.

With the offshore exploration industry putting more focus on QHSE and encouraging companies to move from manual to digital solutions, the demand has increased for alternatives to traditional paper-based safety regimes. The combination of remote locations, the exploitation of highly explosive materials, and the harsh environment has given the industry constant and pressing concerns about the safety of their personnel.

Rfid mustering and emergency response management

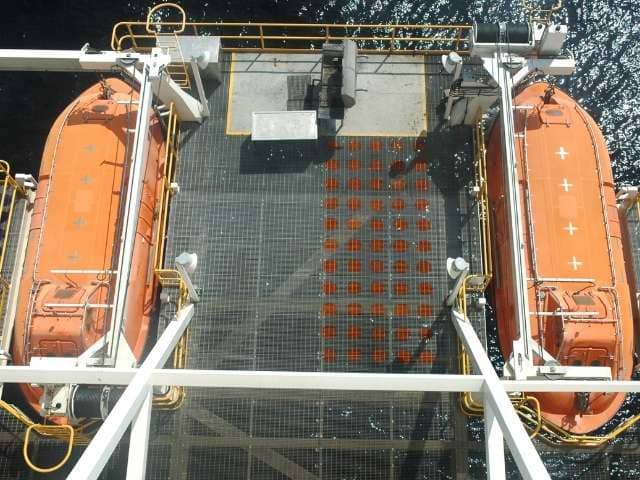

In an emergency, the crew of an offshore rig is instructed to muster. Depending on their tasks, mustering can happen at specific locations for specific tasks (e.g. fighting fires, conducting search and rescue, occupying command posts) or to muster in evacuation areas. Once the word is given to abandon the offshore installation, all personnel head toward the lifeboat section and call there to board the assigned rafts.

Offshore drilling is, not only in rough climate zones, an activity performed in a harsh environment under hazardous conditions with many risks involved. Life safety is essential in high-risk surroundings where a single mistake can result in disaster. Accuracy and time could mean the difference between life and death for many people. Automated mustering using RFID is an integral part of an advanced emergency response management.

Emergency Response - Are you prepared?

As offshore structures are placed further from shore and in more challenging environments, personnel in the renewable energy industry face an ever-increasing level of risk. To mitigate these risks, emergency response must be readily available, and a focus on well-practised processes and procedures through regular drills and exercises is essential for effective command and control of events and responses.

This articles introduces into the different roles in an offshore emergency procedure and what their duties are - based on the example of the HM Coast Guard.

Offshore Emergency Response with Jake van den Dries

In the rapidly evolving world of Health, Safety, and Environment (HSE), there are a few individuals whose dedication, expertise, and innovative spirit stand out. Jake van den Dries is one such stalwart in the HSE domain. With his experience that speaks volumes, Jake has been a beacon of change and advancement in the HSE sphere. Today, we are privileged to have an insightful conversation with him, delving deep into his vast experience and the challenges he has faced over the years. Join us as we uncover the intricacies of HSE through the lens of one of its most esteemed practitioners.

Offshore Emergency Response Software

It's hard to overstate the importance of quick, efficient emergency response on FPSOs and drill ships because they deal with high stakes. Maritime giants like these operate in some of the most challenging environments on the planet, with thin margins for error and serious consequences if they fail. It's in situations like these when traditional methods of emergency response and personnel counting don't cut it. This is where electronic mustering (e-mustering) as an emergency response software comes in handy.

Offshore Emergency Response and HSE standards

The North Sea is synonymous with challenging offshore environments and equally stringent Health, Safety, and Environment (HSE) regulations. These regulations are critical in safeguarding human life and the marine environment from the inherent risks of oil and gas extraction and energy production. The United Kingdom, Norway, and Denmark, major stakeholders in this sector, each have their regulatory frameworks designed to uphold the highest HSE standards. This article delves into the specifics of each country's laws and contrasts their unique approaches to maintaining safety and environmental integrity.

Emergency Response Notification

Whether it’s oil and gas exploration or green wind energy, offshore safety is crucial due to the nature of the seas and demanding, often hazardous, work environments. The situation can go from zero to one hundred in a blink of an eye - emergencies can occur without any warning. Quickly notifying and updating crew members on Service Operation Vessels or Floating Production Storage and Offloading units, and oil rigs can really save lives. This blog post explores emergency response notification systems and looking deeper into their technical aspects.

Offshore Emergency Response on FPSO

Blaring alarms, heavy smoke, navigating through the maze of installations and the relentless ocean around. Confined spaces, unpredictable conditions, and emergencies like fires, explosions, or structural damage escalate within moments, forcing the crew into a high-stakes race against time. It's hard to imagine what's going on in a crew member's head during these situations.

That's why emergency response management is not just technical needs but a lifeline in themselves. They provide a response to the unpredictable, a beacon of safety in the most horrifying circumstances. Understanding the human element, along with the environmental realities of emergency response solutions and evacuating an FPSO, underlines the importance of careful planning, advanced technologies, and emotional resilience in ensuring that everybody gets home safely.

Emergency Response Management and e-POB

Safety management on Floating Production Storage and Offloading (FPSO) units demands uncompromising precision due to the isolated, high-risk nature of offshore operations. Effective safety protocols are vital to safeguard lives and maintain operational continuity, from fire prevention and hazard control to personnel tracking and emergency response. In this article, we discuss comprehensive safety practices on FPSOs, the role of real-time POB (Personnel-on-Board) systems, and the advantages of hands-free, automated e-POB technologies in enhancing accountability and emergency readiness.

VW Autostadt Infographic

The Autostadt in Wolfsburg focuses on all aspects of mobility. The theme park and educational centre is one of the most popular tourist destinations in Germany. The Autostadt is also the world's largest new car delivery centre and home to the multi-brand ZeitHaus car museum.

Emergency Response Management: Mobile mustering

Cruise ships, extensive facilities, mass events, big office buildings, offshore installations and mines must prepare for an emergency evacuation scenario.

When safety managers use traditional mustering methods, inaccurate data will lead to dangerous situations for personnel, visitors and rescue teams.

A mobile mustering solution based on automatic scanning of the entire area will provide a much better overview of the situation and help emergency response management where needed.