LKAB: 10 years of partnership with Identec Solutions

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

Kiruna is an absolute stunner. North of the Arctic circle and still covered by snow in April, the town has its charm. But the best part lies underground - a high-tech mine of superlatives: 75,000 tonnes of iron ore mined per day. The latest explorations revealed 800 million tonnes of known iron ore reserves in Kiruna alone (learn more about the mining industry in Sweden

).

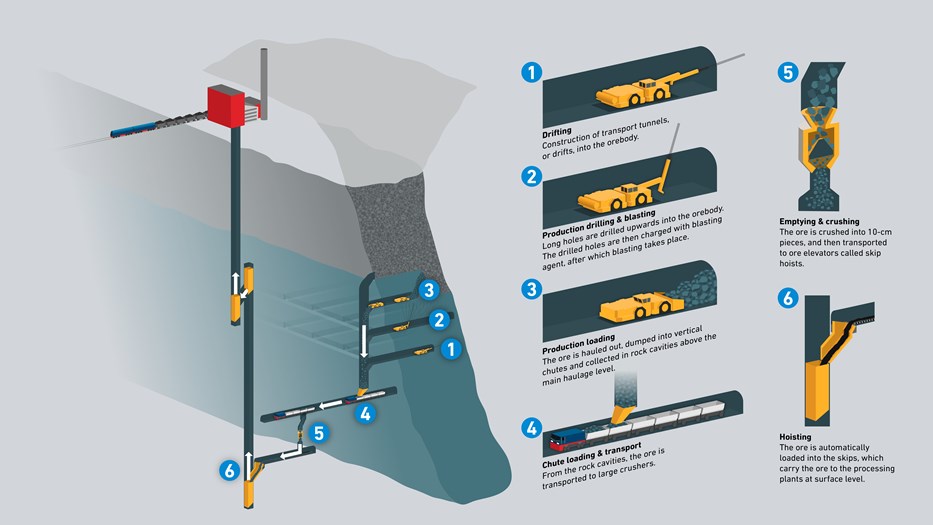

Because of the geological settings in Kiruna, the ore is extracted from LKAB's underground mines using sub-level caving. This method is based on creating cavities in the orebody through drilling and blasting. It allows the ore to fall to underlying levels utilizing gravity and then transported onwards by train or loader. Once the ore is removed, waste rock collapses down and fills the cavity. The result becomes visible on the ground above: it sinks. Because of the massive dimension of the ore body, the town itself must be moved over the years to make room for the caving.

Illustration (c) LKAB

The mining process itself is separated into several stages:

- Drifting: Transport routes are built into the rock. These tunnels are wide enough for oversized machinery and are reinforced with bolts, mesh and sprayed concrete.

- Production drilling: Once the development drifts are ready, long holes are drilled upwards through the ore body and special explosives are pumped into them. Blasting is performed every night.

- Production loading: When blasting is complete, and the blast fumes have been ventilated away, the iron ore is removed from the drifts by underground loaders. The ore is tipped into vertical shafts and collected at the bottom in bins to be transported to the next main level.

- Chute loading/transport: The ore is transported from the rock bins to giant crushers using driverless trains.

- Emptying/crushing: The crushers break the ore into pieces measuring around 10 centimetres, then transported them on long conveyor belts to the skip hoists.

- Hoisting: The ore is hoisted to the surface. Each skip can lift 40 tonnes of ore at a time at 17 metres per second.

Due to this process, a large workforce works at the main level of 1345 below the entrance. The safety concept, based on zone coverage, registers every access to the mine and the movements of every worker there.

Ten years ago, LKAB investigated possibilities to automatically show the position of every single worker in the mine. A WiFi-based concept was not reliable enough; instead, the LKAB project team trusted a reliable technology: RFID. Identec Solutions provided what LKAB needed. The rest is history.

Today, the technology is still in use and is constantly upgraded. As the mine grows further into the ore body, more tunnels and shafts must be covered to enhance the zone concept. With Crew Companion, this is the easy part: LKAB automation engineer Tobias Johansson installs the devices by himself, Identec Solutions updates the database, and the new readers are active.

For more information about LKAB, their business and their usage of Crew Companion, please download our success story "LKAB: Operational Reliability for a Sustainable Future".

Related Articles

Related Product