Mining risk management and wearables

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

Table of contents:

- Health & Safety Regulations In Mining

- How Do We Cope With Risks And Hazards?

- Safety Analysis And The Human Factor In Risk Management

- Training Is More Than Practice: Insights Through Drills

- How Can Wearables Help Improve Safety Standards?

- Added-Value Of Wearable Transponders

- Glossary

HEALTH & SAFETY REGULATIONS IN MINING

Health and safety in the mining industry have always been an important aspect of operations. In these COVID times, health will probably become the most discussed topic in our societies globally. The resulting disruptions of economic activities triggered talks, strategies and concrete actions on how to strike a balance between the safety needs of the population and the well-being of economic life. This balance is, and always was, at the centre of mining operations – the health and safety concerns of miners and the return on investment for operators.

Safety standards vary greatly across the globe (1). The highest standards are in Europe, North America and Australia, in stark contrast to some parts of Africa or Asia where mines lack the most fundamental safety infrastructure and procedures.

Advanced safety standards have been made mandatory with the help of the Mine Safety and Health Acts (2, 3, 4, 5) to improve safety and working conditions. The International Labour

Organisations ILO (6), the International Organisation for Standardisation ISO (7), and the OHSAS add to the breadth of international health and safety regulations for the mining industry.

Health standards include preventive measures (e.g., the black lung program), regular health checks and the mandatory usage of protective devices (e.g., respiratory masks). They also regulate the usage of materials and tools within the mine, approval requirements for explosives, hydraulic fluids, and electric lamps, communication systems, dust and methane detectors, and vehicles. In addition, safety regulations also describe the necessary training of miners and mine rescue teams in safety-related matters.

How do we cope with risks and hazards?

Despite national and international regulations, mining and quarrying is still the sector with the highest level of work-related health problems in the European Union (11). On the positive side, mining has “only the seventh-highest total number of fatal accidents at work in the EU and continues to improve its records.

On a global level, the health and safety issues in the mining industry are much worse. The non-existence of regulations causes thousands of fatal incidents per year. However, the existence of safety regulations doesn´t by itself prevent accidents, even on a smaller scale. The Department of Mineral Resources highlighted this by commenting that “very few people have accidents for which there is no procedure in place, and we have a significant degree of accidents as a result of people breaking the rules, ignoring rules, or simply not knowing about them…”

Research in the industry showed (9) that rules and regulations are well-intended but not always helpful. Management and regulators should not produce more rules and descriptive safety plans, as they won’t resonate with the workforce. Instead, fewer rules but of higher quality create a better understanding among miners. The Swedish mining industry followed this approach in the early years of 2000 (10) and was focused on risk management.

The top priority in risk management is always to eliminate risks as much as possible and follow a three-level hierarchy of control approach. The first level eliminates the hazard and the associated risk and is the most effective measure of control (e.g., no holes in the floor

where people work). If this is not reasonably practicable, risks should be mitigated by substituting the hazard with something safer (install guard rails). The third level acts as an administrative control to minimise exposure to a hazard (warning sign or protective

equipment).

The top risks in mining related to the health of miners are dust inhalation, constant loud noise, musculoskeletal damage, thermal stress, and chemical hazards. Potential safety hazards include ground stability and rockfalls, mobile plant roll-overs, fire and explosion, loss of ventilation, the inrush of water, entanglement in machinery, falls from height, and injuries from handling heavy loads.

Over the decades, health risks have been reduced dramatically through the application of regulations. The probability of safety hazards diminished over time, as well as new technology improved the construction, infrastructure, and operation of mines. Yet the road to zero harm remains far. The future of mining lies in more challenging environments and more difficult exploration, resulting in higher safety risks. In one sentence, health and safety hazards will remain part of the mining business for the coming decades.

Read more about blasting safety...

Safety Analysis and the Human Factor in Risk Management

Safety analysis is the state-of-the-art approach to improve safety. It can be conducted in every phase of the mine lifecycle – from the planning stage, the construction phase, and the operational stage (12). During operations, for example, safety and risk analysis are used to check if tasks are conducted safely. The following approaches are used to identify and evaluate hazards in operational mines:

- Hazard and Operability Study (HAZOP): A systematic (and therefore time-consuming) approach for identifying hazards by questioning how each part can deviate from the intention of the design and its consequences. It also considers the causes and consequences of human errors.

- Stop, Look, Analyse, Manage (SLAM): Used by individuals, this tool identifies hazards and control methods for tasks.

- Checklist: Easy-to-use method to check compliance with standards and ensure common problems are not missed, but it is difficult to discover new hazards.

- Fault Tree Analysis (FTA): Based on a single fault, incidents are analysed backwards to identify the causes.

- Job Safety and Environmental Analysis (JSEA): This approach identifies hazards for single tasks, assesses the risks and applies insights into developing work procedures.

As mining is geared toward more challenging and exposed environments and undertakings, mining operations become more complex and challenging (13). Interestingly, mechanization

significantly increased the overall risk for accidents but lowered the mortality rate (10). Still, nine out of ten accidents in mining are triggered by human activities such as operator errors and violations of regulations.

Considering these facts, safety analysis is only one part of the overall safety and health strategy in mines. It has been shown that the human factor triggers most accidents in mines (10). The workforce argues that effective rules should provide only minimum standards, be simple and practical, and be flexible to work tasks (9).

Illustrated procedures, consistent and ongoing training and education, and an established safety culture are the best ways to foster safety awareness and reduce incidents in mines.

Training is More Than Practice: Insights Through Drills

As with any management system, a continuous improvement process should be implemented by monitoring and updating the rules and regulatory subsystem at mines at regular intervals. Training is an important part of acquiring and enhancing safety-related knowledge and practical skills in emergencies.

In general, training (“drill”) on machinery or procedures aims to learn and master the desired outcome. The principal objectives of drills in mines are to train the behaviour of miners, to detect errors in (operational and emergency) plans and to minimise the reaction time in case of unexpected events. At the end of the training, each participant should know the answers to “What must be done? What should be done? With what, and when, should it be done?”

Scheduled drills can be carried out after basic instructions have been given. Participants know that a drill will be held and are aware of the procedures. Every drill is an exercise that must be evaluated in the aftermath to deepen the effect of the training. Once scheduled drills have been carried out several times, unscheduled drills may take place. A thorough evaluation will reveal the status of skills and the organisation's weaknesses in performing the desired reaction.

Safety and emergency-related drills are not only important, but also very effective in teaching behaviour for a given scenario. Such scenario-based drills are common practice, for example, in the offshore industry and contribute to very high safety standards, and consequently to a low incident rate.

Evaluation of scheduled and unscheduled drills makes arriving at a critical assessment possible. It should aim to determine whether the workforce involved could solve the task adequately and efficiently, and how to improve the procedure overall.

How Can Wearables Help Improve Safety Standards?

To enhance the learning effects, drills should be monitored by electronic equipment. Video and other technologies are useful for explaining and illustrating the outcome of actions taken. As cameras are not available in all areas where drills are conducted, other monitoring devices would be helpful in delivering visibility. One alternative is wearables.

Wearables are transponders or tags worn on the body that transmit data like heartbeat, body temperature, or step count. The big advantage of wearables is that they display individual behaviour and reactions, preferably in real-time. In the context of mine safety, one of the most important drills is to teach behaviour in case of an emergency like a fire, explosion, water ingress or collapse of parts of the mine. Scheduled and unscheduled evacuation drills can be

monitored by wearable transponders that transmit their positions at any given time.

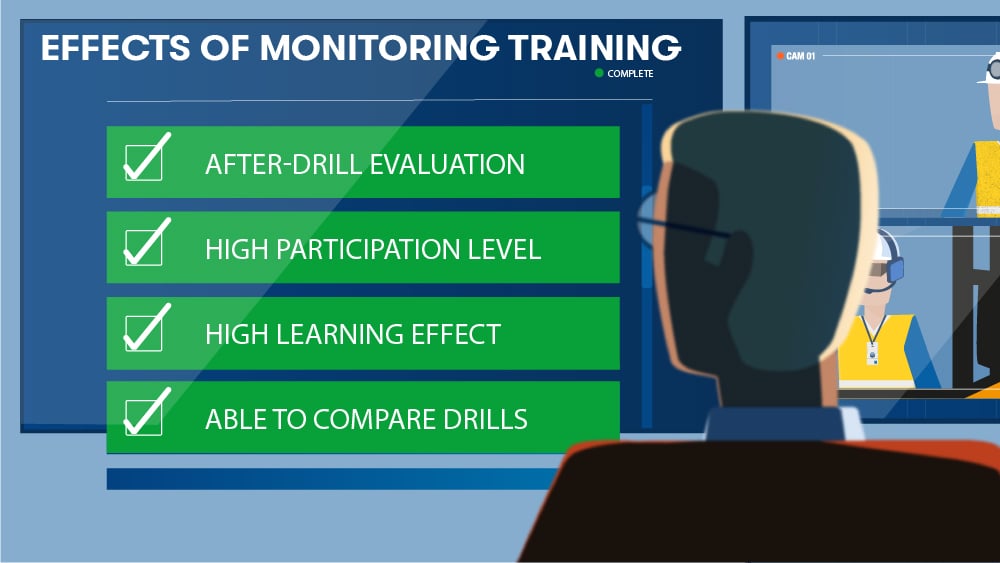

Such transponders show positive effects during training:

- Emergency exercises are individually recorded for after-drill evaluation

- They increase the participation level because of the individual recording

- They improve the learning effect through the evaluation of objective data

- They show improvements by comparing previous drills

- They also provide a realistic time and behaviour framework in case of a true emergency

Added-Value of Wearable Transponders

Position-broadcasting wearable transponders not only help to increase the value of safety training, but they are also valuable in showing the position of each miner in case of a real emergency (learn more about a safety framework in mining). Following the above-mentioned model of 3 levels of risk management, wearables can be successfully deployed to mitigate the risks at all three stages:

Level 1 - Avoiding hazards at all: Close off areas and control site access. Wearables act as keys to mines in general but also to certain areas (e.g., explosives storage)

Level 2 - Safeguarding against hazards: Reporting the safe zone position of every worker in the mine in case of a scheduled blast.

Level 3 - Warning of hazards: In case of an emergency, a transponder indicates the current position and the route to safety.

These examples show that the safety, risk management and continuous operation of a mine are aligned. Wearable individual transponder systems not only save lives in case of an emergency, but prepare the organisation for any eventuality, as drills are documented and comply with governmental, industry and international regulations. Mine operations can continue faster as reduced muster times mean work can be conducted closer to the scheduled blast time and resume more quickly after.

In all scenarios of underground mine safety, everyone involved in mine operations can rely on a digital, real-time reporting system. Operators have the responsibility to answer questions about the whereabouts of their missing workers in an emergency as well as to act in a safe manner during regular operations.

Dive into our core topic: Mining safety!

Glossary

Mining Hazards - The most common mining hazards include, but are not limited to, ground collapse, subsidence, fault reactivation and fissures, mine water rebound, acid mine water drainage, mine gas emissions, and combustion. Other well-known hazards include mining-induced landslides, mining-induced seismicity, waste, dereliction, and contamination. Mining hazards, while sometimes observable, cannot always be forecasted or predicted with regard to their time, place, length, intensity, or area. Mining hazards can happen alone or together as a group. (14)

Sources

(1) Elgstrand, Kaj & Vingard, Eva (2013): Occupational Safety and Health in Mining. Anthology on the situation in 16 mining countries. In: Arbete och Hälsa, vol 47/2. University of Gothenburg. https://gupea.ub.gu.se/bitstream/2077/32882/1/gupea_2077_32882_1.pdf

(2) Mine Safety Regulations in the United States of America (Mine Safety and Health Administration, MSHA): https://www.msha.gov/regulations

(3) Mine Safety in the UK: https://www.hse.gov.uk/mining/index.htm

(4) Mine Safety regulations in Australia: https://www.safeworkaustralia.gov.au/industry_business/mining

(5) Safety and Health in European Mining: http://ltu.diva-portal.org/smash/get/diva2:995436/FULLTEXT01.pdf

(6) Safety and Health in Mines Convention (1995, No. 176) http://www.ilo.org/dyn/normlex/en/f?p=NORMLEXPUB:12100:0::NO::P12100_INSTRUMENT_ID:312321

(7) ISO/TC 82 Mining, ISO/TC 94 Personal Safety, ISO/TC 262 Risk Management

(8) OHSAS 18000

(9) Laurence, David (2005): Safety rules and regulations on mine sites – the problem and a solution. In: Journal of Safety Research, vol 36/1, pages 39-50; https://doi.org/10.1016/j.jsr.2004.11.004

(10) Lööw, Joel & Nygren, Magnus (2019): Initiatives for increased safety in the Swedish mining industry: Studying 30 years of improved accident rates. In: Safety Science, vol 117, pages 437-446. http://dx.doi.org/10.1016/j.ssci.2019.04.043

(11) European Commission (2010)

(12) Harms-Ringdahl (2013): Guide to safety analysis for accident prevention. IRS Riskhantering AB: Stockholm.

(13) Hartmann, Howard & Mutmansky, Jan (2002): Introductory mining engineering. Wiley: Hoboken.

Note: This article was updated on the 5th of August 2025. This article was partly created with the assistance of artificial intelligence to support drafting. The head image was generated by AI.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.