Toolbox talks on safety: Improve the workplace

| Written by Mark Buzinkay

The mining industry, known for its challenging and often hazardous work environment, demands an unwavering commitment to safety. In such settings, even minor oversights can lead to significant accidents, making vigilant safety practices essential. Among the various strategies to promote workplace safety, 'toolbox talks' have emerged as a crucial component. These brief, informal meetings focus on specific safety issues, offering a platform for interactive learning and awareness.

This article delves into the essence and effectiveness of toolbox talks within the mining sector. These talks are not just another formality; they are pivotal in cultivating a culture of safety that goes beyond compliance, fostering an environment where every employee is an active participant in ensuring their well-being and that of their colleagues. Here, we explore how toolbox talks, when correctly implemented, can significantly mitigate risks and enhance safety in one of the most demanding industries.

No video selected

Select a video type in the sidebar.

Table of contents:

- So, What Are Toolbox Talks On Safety?

- Key Elements Of Effective Toolbox Talks In Mining

- How To Conduct Toolbox Talks On Safety?

- Toolbox Talk Example: Eye Protection

- Case Study: Successful Toolbox Talk Example In A Mining Company

- Today's View

- FAQs

- Takeaway

- Glossary

To increase awareness of workplace hazards and improve safe behaviour, toolbox talks are an easy way to keep safety front and centre in their workers' minds. These short pre-written safety meetings are not intended to replace formal OSHA safety training, but to supplement it.

So, what are toolbox talks on safety?

Toolbox talks are short, informal meetings typically held at the start of a work shift or before undertaking a specific task. Unlike formal safety training sessions, which are often comprehensive and conducted in classroom settings, toolbox talks are more focused and relevant to the immediate work environment and tasks. These talks usually last between 5 to 15 minutes and are designed to address specific safety concerns relevant to the day's work.

In mining, where workers face unique and evolving risks, toolbox talks are precious. They provide supervisors and safety officers a platform to highlight recent incidents, discuss potential hazards, and review essential safety procedures. This routine ensures that safety remains in every worker's mind and is not lost amidst daily operations.

Furthermore, toolbox talks are about more than just disseminating information (e.g. ATEX explained). They are interactive sessions where workers are encouraged to share their experiences, concerns, and suggestions. This participatory approach not only enhances the relevance of the information shared but also fosters a sense of collective responsibility towards maintaining a safe working environment.

By routinely focusing on different aspects of mine safety – from equipment use and maintenance to emergency response procedures – toolbox talks are critical in reinforcing safety knowledge, promoting best practices, and building a solid safety culture within the mining industry. Just as an example, each year, UK fire brigades attend over 40,000 fires in workplaces. And every year, more than 40 people are killed and over 2500 injured in these fires. If any of those short talks can prevent 1 accident or fatality, it’s worth having them. (1)

Interested in establishing a safety culture in mining? Read more about underground mining safety!

Key Elements of Effective Toolbox Talks in Mining

In the mining industry, where every decision can significantly impact safety, the effectiveness of toolbox talks is not just about the content but also how they are conducted. Here are the key elements that make toolbox talks particularly effective in a mining setting:

- Brief, focused, and relevant content: The success of a toolbox talk lies in its brevity and relevance (remember the 5-minute rule). Talks should focus on specific hazards or safety procedures pertinent to the day's work. For instance, the talk should cover landslide awareness and emergency procedures if a team is working in an area prone to landslides. This focus ensures that the information is immediately applicable and easily retained.

- Active participation and engagement: Engagement is crucial. Toolbox talks should encourage interaction, allowing miners to share their experiences, ask questions, and propose solutions. This participatory approach makes the sessions more engaging and helps identify potential hazards from the miners' perspectives. For example, a miner might share an observation about equipment wear, leading to a discussion on regular maintenance checks.

- Frequency and timing: Regularity is key in toolbox talks. Holding these talks daily or before each shift ensures safety is always at the forefront. Additionally, the timing of the talk can influence its effectiveness. When workers are more alert and focused, conducting it at the beginning of a shift can ensure better attention and retention of the information shared.

- Leadership and responsibility: Supervisors and safety officers play a pivotal role in driving the effectiveness of toolbox talks. They must not only be knowledgeable about safety practices but also skilled in communication and engagement techniques. Their attitude towards safety can significantly influence the team's attitude. For instance, a supervisor who consistently reinforces the importance of safety gear usage sets a standard for the team.

- Variety and creativity in delivery: Varying the format and delivery can keep the talks engaging and avoid monotony. This can include using visuals, real-life incidents, demonstrations, or guest speakers. For example, using a recent incident report as a case study can make the dangers more real and the need for safety protocols more urgent.

- Follow-up and continuity: Toolbox talks should not be viewed as standalone sessions. Follow-up on previous talks, checking if measures discussed were implemented, and periodically revisiting topics can reinforce essential safety messages. For example, if a new safety procedure is introduced, subsequent talks can include feedback sessions on its implementation and effectiveness.

How to conduct toolbox talks on safety?

Following a few simple rules when conducting a toolbox talk for your workers, toolbox talks are an effective channel to improve safety at the workplace:

- Prepare yourself: Read the toolbox and talk to yourself a couple of times before you hold the actual meeting with workers.

- Hold the talk in an area free of noise and other distractions.

- Speak clearly and directly.

- Use examples to educate and show your audience what you are talking about, best using a real object. For instance, have an unlabeled container you found on the job site available when giving a toolbox talk on OSHA’s hazard communication standards about labelling requirements.

- Always give the opportunity to ask questions at the end of the toolbox talk.

- Don't forget to document your toolbox talks. Even if certain standards do not require documentation of safety training, it is worth recording the information about the topic, the trainer, the date, and the names of the workers on file.

- Practice what you preach. Otherwise, your credibility will vanish rapidly. Always set a good example for others.

Further reading: Mine Safety - Why digital management?

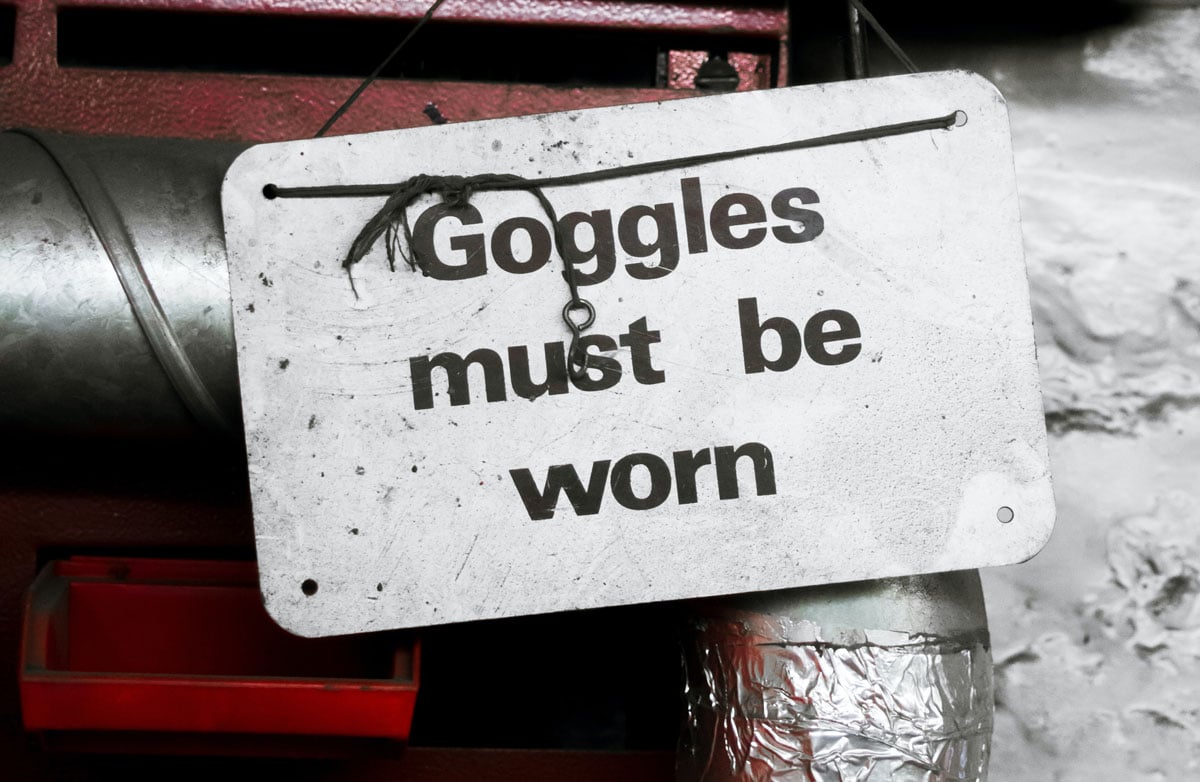

toolbox talk example: Eye protection

Intro to get attention

It may be difficult getting used to eye protection, but have you tried getting used to a glass eye?

Educate

There are two kinds of foreign particles that can get into your eyes. Wind-carried material like sawdust and rust. Or high-speed objects like broken nails or flying chips of concrete.

To protect your eyes from these objects, wear safety glasses, safety goggles, face shields and prescription glasses with safety lenses. Each has a different use depending on whatever conditions that exist for your particular job site. It is very important to make sure that your eyewear fits correctly. Remember that proper ventilation and sprays can help reduce fogging.

Showcase

Find a few old pairs of goggles that have nicks and scratches on them. Point out the marks and tell them that those are the places where chips would have gotten into their eyes, without eye protection.

Ask to start the talk:

- What kind of jobs need eye protection?

- Has anyone heard of a serious accident involving someone who wasn't wearing eye protection?

Case Study: Successful Toolbox Talk Example in a Mining Company

To illustrate the impact of compelling toolbox talks in the mining industry, let's examine a case study from a mining company.

Specific Safety Challenges Faced

- Challenge 1: Increasing incidents of machinery-related accidents due to improper handling or maintenance.

- Challenge 2: Geological unpredictability leading to minor rock falls and landslides.

Detailed Walkthrough of a Toolbox Talk Session

- Topic: Enhancing Awareness and Prevention of Machinery-Related Accidents.

- Objective: To educate the workforce about proper machinery handling and maintenance procedures.

- Content:

- Introduction to the recent machinery-related incidents within the company.

- Detailed explanation of proper machinery handling techniques.

- Maintenance schedules and checklists for critical equipment.

- An interactive session with workers sharing their experiences and best practices.

- Methodology:

- Use of visual aids such as diagrams and actual equipment for demonstration.

- Q&A session to clarify doubts and encourage worker participation.

- Duration: 15 minutes.

Impact and Results

- Short-Term Impact:

- An immediate reduction in machinery-related incidents in the following month.

- Enhanced worker engagement in safety practices.

- Long-Term Impact:

- Development of a comprehensive machinery safety protocol based on feedback from the talks.

- Sustained reduction in incidents and enhanced compliance with safety procedures.

- Employee Feedback: Workers expressed a higher sense of safety awareness and appreciated the interactive nature of the talks.

This case study suggests how a well-structured toolbox talk can address specific safety issues effectively. By focusing on immediate concerns (machinery-related accidents) and incorporating interactive elements, the company not only improved its safety record but also fostered a culture of proactive safety engagement among its workers. This approach, highlighting both the immediate and long-term benefits of toolbox talks, serves as a model for other mining companies aiming to enhance their safety standards.

TODAY'S VIEW

In 2024, advanced technologies and data analytics will be used to make the toolbox talks on safety more effective. Workers can now participate in an immersive safety training experience made possible by the use of Virtual Reality (VR) and Augmented Reality (AR). This makes the learning process more substantial. Moreover, wearable devices and IoT sensors enable real-time information on the health status of workers and environments, making it easier to have focused and timely safety-oriented discussions. These technological innovations, together with the traditional interactive components, make sure that toolbox talks stay relevant and very effective in dealing with the dynamic challenges to safety in the workplace today (2).

FAQ

How often should toolbox talks on safety be conducted in the mining industry?

Safety toolbox talks should be done, at a minimum, at the start of each day's work or prior to some specific tasks. This ensures that safety remains at the top of the mind and allows for any new or emerging hazards to be discussed in a timely manner. Daily talks, therefore, make sure workers are reminded consistently of where safety procedures stand, what has occurred recently, what incidents have happened, or what changes have been made in procedures—building a culture of continuous safety awareness.

What topics are typically covered in toolbox talks on safety?

Safety toolbox talks cover a whole lot of relevant issues at the workplace and tasks to be carried out. Common topics include proper use and care of equipment, hazard identification and response, emergency procedures, use of personal protective equipment, recent incidents, and mishaps from elsewhere with lessons drawn. In the case of the mining industry, they could also be tailored to provide information on concerns specific to issues like landslides, machinery, underground ventilation, and working protocols applied in the handling of dangerous substances. The objective focuses on practical safety concerns that could be faced daily by employees.

Takeaway

Toolbox talks about safety, which is a vital tool in reinforcing workplace safety, especially in high-risk industries like mining. These short, focused meetings, held at the start of shifts or before specific tasks, serve as a crucial supplement to formal safety training. By addressing immediate safety concerns relevant to the day's work, toolbox talks keep safety at the forefront of workers' minds, promoting a culture of proactive safety engagement. Their interactive nature encourages worker participation, enhancing the relevance and retention of safety information. Effective toolbox talks, characterised by their practicality and engagement, are instrumental in reducing workplace incidents and fostering a strong safety culture.

Workplace and operational safety are among the areas of expertise of IDENTEC SOLUTIONS. Awareness & training reduce the risk of incidents and enable smooth and productive operations.

Delve deeper into one of our core topics: Mining safety

Glossary

Occupational Safety and Health Administration (OSHA) - the agency that is a branch of the United States Department of Labour that originally had federal investigatory powers to inspect and examine workplaces. Congress established the agency under the Occupational Safety and Health Act (OSH Act), which President Richard M. Nixon signed into law on December 29, 1970. OSHA's mission is to "assure safe and healthy working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education, and assistance." The agency also has a mandate to enforce an array of whistleblower statutes and regulations. OSHA workplace safety inspections have been shown to reduce injury rates and injury costs without negative impacts on employment, sales, credit ratings, or firm survival. (3)

Sources:

(1) https://arlweb.msha.gov/epd/efsms/toolbox/previous.asp

(2) https://www.cdc.gov/niosh/mining/works/coversheet1934.html

(3) https://en.wikipedia.org/wiki/Occupational_Safety_and_Health_Administration

Note: The article was updated on August 5th, 2025. This article was partly created with the assistance of artificial intelligence to support drafting. Some images were generated by AI.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.