Underground mining safety: Implementing a positive Safety Culture

| Written by Mark Buzinkay

Having safety regulations in place does not automatically constitute a safe underground working environment.

In this extended post/whitepaper, we discuss the need for a safety culture in the mining industry.

No video selected

Select a video type in the sidebar.

Table of contents:

- Why A Safety Culture?

- Safety Regulations Are Not Enough

- What Is A Safety Culture?

- How To Implement A Safety Culture

- Underground Mining Safety: Benefits Of A Positive Safety Culture

- FAQs

- Takeaway

- Glossary

As mining has always been a hazardous workplace, safety is a prime concern. Safety laws have been essential to provide fundamental layers of regulation, but have failed to address ignoring or neglecting behaviour. Installing a positive safety culture within the workplace improves employee safety and impacts how employees feel about their company, increasing the positive feelings about their organisation.

Interested in location technology to improve safety for mining - continue here...

WHY A SAFETY CULTURE?

Underground mining has a long history and a long history of accidents. While industry leaders say that the total number of fatalities has decreased considerably since the early 20th century, tragic mining accidents are still happening. Although there are no accurate figures, estimates suggest such accidents kill about 12,000 people a year.

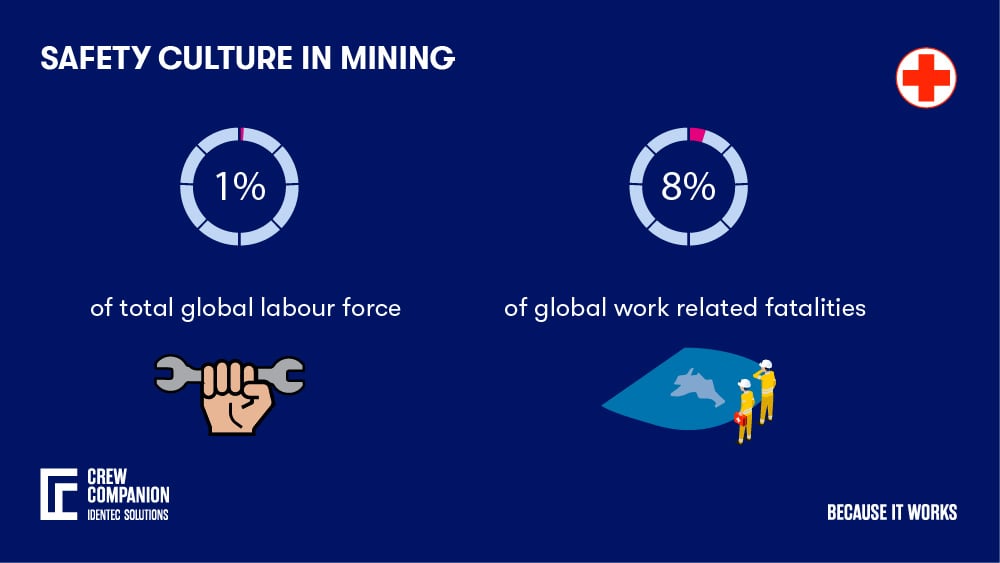

According to the International Labour Organisation (ILO), while mining employs around 1% of the global labour force, it generates 8% of fatal accidents. However, the overall situation appears to be improving, as there is a downward trend in accident severity and fatalities. Moreover, these incidents are dropping with perhaps a few exceptions - countries like China and Russia - as the standards differ significantly from country to country.

China has the world's largest mining industry (up to three billion tonnes of coal/year produced) and accounts for 40% of global coal output. Still, it is also responsible for 80% of mining casualties worldwide. Maximising revenue and seeing the lives of miners depend, safety rules are limited or non-existent. Miners are not able to speak freely for fear of losing their jobs. The weakness of labour laws and the lack of unions keep mines from being safe workplaces.

In the wake of the Chilean disaster in 2010, when 33 miners were trapped for weeks underground and eventually were rescued, the unions around the world have repeated calls for stricter safety standards. Better laws are needed (see also: mine monitoring).

But laws are just part of the solution to creating a safe environment for miners. In 2020, at least 160 jade miners died in a mudslide due to heavy rains in northern Myanmar. The rainy season lasts for four months in Kachin state, and landslides are widespread during this period. Although there are regulations on the mining of jade in the area, no laws are enforced, and there are no follow-ups. Many mining companies do not follow the guidelines at all. As another example, the Mariana mining disaster in Minas Gerais, Brazil, was attributed to the managing companies' severe lack of preparedness and oversight. The dam burst is considered the worst environmental disaster in Brazil's history: The toxic mud of iron ore waste spanned 500 km across two Brazilian states, leaving hundreds homeless and polluting the region's most important river. It impacted mineral water supplies and endangered the livelihoods of the region's fishermen before floating into the Atlantic Ocean.

SAFETY REGULATIONS ARE NOT ENOUGH

Having underground mining safety regulations in place does not automatically constitute a safe working environment. Besides not enforcing regulations, other aspects of negligent behaviour can contribute to hazardous situations:

1. Pushing people through the training program too fast

All workers should be adequately trained for the duties they are expected to perform, and this training must extend to health and safety in the working environment. Proper training on workplace safety provides awareness of potential hazards and how to handle them. But companies can sometimes feel pressured to get employees up to speed as quickly as possible; as effective training takes time, this leads to discrepancies. Following employee progress throughout safety training gives employers further understanding of how well employees grasp the safety guidelines (learn more about safety training for supervisors)

2. Failure to involve the workforce

Employees are very often more aware of workplace hazards and their risks. For this reason, consultation is an important management tool on matters regarding health and safety in the workplace. Many organisations will have a designated health and safety spokesperson, chosen by the employees, who will work closely with the company's responsible person to manage and monitor health and safety. But in general, a lot can be learned by simply listening and talking to your workforce about their duties, the risks, and ways that might improve safety by reducing these risks.

3. Not reporting near misses

While some safety incidents result in workplace injuries, many scenarios don't result in injuries. Shell estimates one injury or fatality per 300,000 incidents. These situations may be written off, as there is no specific injury to report. But companies should take these near-misses seriously. Once registered, these incidents should be investigated and tracked, as should the corrective actions they inspire.

4. Using the wrong tools for a task

To save money, alternate tools may be used to complete jobs in the workplace. A swap can initially save money, but it ultimately makes work less efficient and more dangerous, contributing to higher costs over time. Even if it is more expensive, the tool specific to the task is the only one that should be used. This choice will optimise productivity and improve workplace safety in the long run.

5. Delaying machine maintenance

Workplace accidents can often be attributed to faulty equipment. Machines with problems create a risk for employees who use them and those who work around them. A workspace can be made safer by both noticing when a machine is not operating as anticipated and when a person seems blissfully unaware that there is a potential accident on the horizon. Regular maintenance and inspections are vital in identifying potential risks and initiating prevention tactics. Scheduling inspections in advance is crucial to ensuring the smooth operation of machines and avoiding breakdowns.

The list of potential pitfalls relying solely on safety regulations is dangerously long. It shows that workplace safety depends on other factors, too. Despite the declining accident rate in countries with high standards, accidents lead to further investigations to learn more about the root cause. In most cases, negligence leads to near misses or incidents.

WHAT IS A SAFETY CULTURE?

Ultimately, workplace safety isn't about avoiding legal violations and fines. It's about taking care of each other. Anyone can plunge into bad patterns and become lax about safety, so we must have each other's backs in the workplace. People have to be taught to be more observant.

An organisation's safety culture is the product of individual and group values, attitudes, perceptions, competencies, and patterns of behaviour that determine the dedication to and the style and mastery of an organisation's health and safety management.

Critical aspects of an influential culture are Management commitment, visible management and good internal communications. Responsibility at the Management level is considered vital as it will produce higher levels of encouragement and concern for health and safety throughout the organisation. When it comes to health and safety, managers must lead by example and appear regularly on the 'shop floor', talking about health and safety and visibly demonstrating their commitment by their actions. A positive culture debates health and safety as part of everyday work conversations. Active employee participation in safety is essential to build ownership of safety at all levels and to exploit employees' unique knowledge of their work. Again, listening to the people doing their job is critical. This can include active involvement in workshops, risk assessments, plant design, etc.

A positive safety culture guarantees a proactive take on health and safety. The team is personally invested in their safety and the safety of others. Not only do they follow policy, but they do so willingly with the mindset of looking out for ways to increase site safety, reducing risk and the number of safety incidents that occur. If this is your organisation's safety culture, people who ignore health and safety rules are reported for breaking the rules.

HOW TO IMPLEMENT A SAFETY CULTURE

Implementing a safety culture is a long-term process. The key to a truly positive and effective safety culture is to ensure that everyone understands a single golden rule: Safety comes above all else. Safety is above profits, deadlines, management decisions, and anything. For example, suppose safety is your number one priority and part of your core values (and your staff knows that). In that case, your safety-first attitude will evolve into a successfully developed safety culture (read more about mine safety management).

Besides this golden rule, which steps play a significant role in implementing a safety culture successfully?

Create a corporate vision for safety

Everyone in the company must be on the same page regarding the organisation's vision for safety. Rules must apply to everyone and not exclude any. This leads to resentment. There should be no member of your workforce who gets special treatment and can ignore the safety culture. Everyone is responsible for safe working practices to the same standards in a strong safety culture, from the CEO to the latest apprentice. It is impossible to reach your safety goal if all company stakeholders are not working towards the same target.

Develop a system for open communication

Companies with a strong safety culture invest in creating lines of open communication throughout their organisation. Keeping employees updated on new safety initiatives is vital to successfully implementing policies and practices. Monthly safety talks are a great way to share new information and allow employees to open communication around safety within the workplace.

Involve all levels of employees

Creating a safety culture starts from the ground up. Therefore, employees of all levels must be included in any new safety initiative's planning and implementation phase. Asking for feedback during the initial planning phases increases buy-in and prevents potential pitfalls further down the line during implementation.

Encourage workers to do the right thing

If employees don't feel they can come forward with problems for the risk of inciting anger or creating difficult situations, they won't. If work has to stop to make it safer, then that should always be seen as a good thing, and workers should be reassured they will not suffer as a result of coming forward. This sort of conduct should be encouraged and rewarded, even if it does come with a negative short-term impact on operations.

The reporting system should be focused on the positive, and employees should feel free to share safety matters without repercussions. As the team members are at the heart of your safety culture, they should have a voice in how safety culture is developed and addressed. Asking questions and engaging with the team is the way to go. This will help you identify directions of development and core problems with your current safety culture that you may not even know about. Rewarding employees who share safety issues is a great way to rebuild your system and encourage others to report.

Train employees in workplace safety

If your team doesn't understand how to follow safety practices, then the safety culture will be confused and misrepresented. Sharing best practices and developing opportunities for employees to have hands-on learning sessions helps employees retain and successfully implement new safety initiatives (check: miner technology and wearables).

Training is crucial, and not just during the initial introductory stages. It should also be ongoing to educate on health and safety policy modifications and serve as a reminder of the importance of an excellent safety culture. Additionally, investing in quality training shows employees that you care about their safety, increasing team member buy-in and support.

Management modelling

For any safety initiative to succeed, the procedure must be modelled from the top down. Managers must commit to embodying a safety-first work style and continuously demonstrate that safety is essential and valued. Suppose the management team doesn't take safety culture seriously. In that case, the safety initiative will run into many problems, from the rest of your team not taking it seriously to ineffective policies being implemented because those at the top aren't paying close enough attention.

Reward a good safety culture

Keeping team members motivated and updated about the company's progress is critical to driving safety initiatives. Just as valuable as disciplining rule breaks is rewarding those who follow policy. Establishing health and safety goals and targets, it's common practice to discipline those who don't follow the health and safety policy. This is an integral part of maintaining procedures, but it's not the only step you can take. Just as valuable as disciplining rule breaks is rewarding those who follow policy. Establishing health and safety goals and targets, and rewarding teams that meet those targets, develops a positive mindset toward a safety culture.

Work on continuous improvement plans

New and exciting initiatives can get a lot of buy-ins when they're first introduced, but as time goes by, they can quickly fade into obscurity. A company that truly embodies a safety culture understands that while success must be celebrated, there is always room for some improvement. Committing to constant growth and putting in place systems for continuous improvement ensures your organisation will not remain stagnant in their results but continue to strive for an injury- and accident-free work environment. On the other hand, if you're not constantly improving your health and safety process and keeping awareness fixed upon safe practice, safety culture can become neglected and easily ignored.

Hold employees accountable

Establishing a safety culture with strong values and goals is impossible without including some way of holding everyone accountable for the culture's success. It's a team effort, and every member makes a difference. With that in mind, you need to decide how you're going to recognise success and improve in the areas that need it. Responsibilities within an organisation must be defined at all levels, including policies and goals.

UNDERGROUND MINING SAFETY: BENEFITS OF A POSITIVE SAFETY CULTURE

A positive safety culture not only talks about compliance with regulations but also the root causes of unsafe practices. A company that values safety in its mining operations protects its greatest resource, the worker, and also augments the overall operation efficiency and the morale of the employees. Safety culture ensures a healthy work environment where employees feel good about themselves, safe from danger, valued, and respected, increasing their job satisfaction and decreasing the turnover rate. Safety becomes less costly in the long run, as companies would generally commit to avoiding the expensive consequences of accidents, from medical fees to legal charges and cessation of production. Over the years, this could help to build a reputation for the company of being a responsible and caring employer, attract the best-trained and prepared talent, and make the business more competitive and sustainable. Mining companies can provide an assurance of a safer, more productive, and amiable work environment through the establishment of an organisation where safety is integrated into the basic values and everyday practices.

FAQs

What are the key components of a positive safety culture in underground mining?

A positive safety culture in underground mining is based on several integral elements. Management commitment is the most important one: leaders must show, overall, that they value safety, not only by lip service but also by overproduction and profits. Employee involvement in safety conversations, training, and general decision-making is very significant. In addition, there should be clearly outlined lines of good communication that are open about any safety-related concerns. What is most important is that continuous training should equip each employee with the knowledge of safety protocols and best practices. In order to promote a positive safety culture, there could be accountability for safety from all employees and reward systems for following safety practices. Last but not least, regular inspection and maintenance of the equipment must be ensured and maintained so as to avoid any machine failure leading to an accident.

How can underground mining companies improve their safety practices?

There are various ways in which underground mining companies could focus on their safety culture. Detailed training programs should be put forward so that all employees are trained appropriately regarding measurements for safety and risk situations. Regular safety audits facilitate spotting potential hazards before they turn into mishaps. Near-miss reporting promotes the trend of a culture where workers will feel free to provide reports about near-misses to address risks ahead of time. Investments in safety technologies, such as wearable sensors and automated monitoring systems, could enhance safety. Adoption of a culture of safety first—that is, enshrining safety as part of the mission—ensures that the issues arising are really at all levels within an organisation. Continuous improvement regarding the regular updating of safety protocols with new findings and feedback will keep safety practices current with the industry's changing needs.

TAKEAWAY for underground mining safety

Installing a positive safety culture within the workplace enhances employee safety and influences the way many employees perceive their company, ultimately enhancing the organisation's reputation. Although implementing a safety culture is a long-term process, it also has long-term positive effects on workplace safety, avoiding loss of lives, health and assets. Positive safety culture is the living proof that safety comes above all else.

For current trends, see: Mine Safety Topics 2025

Delve deeper into one of our core topics: Mining Safety

Glossary

The International Labour Organisation (ILO) is a specialised agency of the United Nations, whose mandate is to advance social and economic justice by setting international labour standards. Founded in October 1919 under the League of Nations, it is the first and oldest specialised agency of the United Nations. The ILO has 187 member states: 186 out of 193 UN member states plus the Cook Islands. It is headquartered in Geneva, Switzerland, with about 40 field offices around the world, and employs some 3,381 staff across 107 nations, of whom 1,698 work in technical cooperation programmes and projects. (7)

Sources:

(1) https://www.dw.com/en/mining-disasters-continue-in-myanmar-despite-regulations/a-54042106

(2) https://www.bbc.com/news/world-latin-america-11533349

(3) https://webdoc.france24.com/brazil-dam-mining-disaster-mariana/

(4) https://www.hse.gov.uk/humanfactors/topics/common4.pdf

(5) https://www.ilo.org/resource/other/safety-and-health-underground-coalmines

(6) https://www.tdi.texas.gov/tips/safety/minesafety.html

(7) https://www.ilo.org/about-ilo

Note: This article was updated on the 5th of August 2025. This article was partly created with the assistance of artificial intelligence to support drafting. The head image was generated by AI.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.