Walk-to-work or how to make offshore transfers safe

| Written by Michal Wozniakowski-Zehenter

The emergence of the Walk-to-Work (W2W) approach promises a new era: By utilising specialised vessels equipped with motion-compensated gangways, this approach has revolutionised offshore crew transfers, enhancing both safety and efficiency.

No video selected

Select a video type in the sidebar.

Table of contents:

- Challenges In Crew Transfer

- Walk-To-Work Gangways

- Walk-To-Work: What Is The Benefit?

- Walk To Work: This Is The Way

- FAQs

- Takeaway

Gone are the days of relying solely on helicopters or baskets to transport crew members. With the Walk-to-Work approach, workers can now be safely transferred between installations and vessels without having to face the dangers associated with traditional methods. The motion-compensated gangways ensure stability and reduce the risk of accidents that can occur during transfers. Walk-to-Work systems have been used successfully in the UKCS since early 2006, and globally have transferred over 800,000 personnel.

Moreover, the Walk-to-Work offshore approach also brings about significant cost savings. By eliminating the need for expensive helicopter transfers or complex basket systems, companies can allocate their resources more effectively, improving safety and operational efficiency at the same time.

The specialised vessels used in the Walk-to-Work approach feature advanced stability systems and are designed specifically for offshore crew transfers, considering the unique challenges faced in these environments.

Challenges in Crew Transfer

One of the main obstacles faced in offshore crew transfer is the relentless battle against harsh weather conditions.

Offshore installations are exposed to severe weather like storms, strong winds, heavy rainfall, and turbulent seas because of their secluded position. This poses significant risks to crew members during transfer operations. To conquer this challenge, the implementation of advanced weather monitoring systems becomes crucial.

These systems provide real-time data on weather conditions, enabling decision-makers to determine the optimal periods for crew transfer.

By conducting operations during relative calm, the risks associated with harsh weather can be minimised.

Additionally, the utilisation of cutting-edge vessel stabilisation technologies, such as active motion compensation systems, can help counteract the effects of rough seas, enhancing the stability and safety of transfer operations.

The remote locations of offshore installations also present unique safety concerns as they have limited access to medical facilities and emergency services.

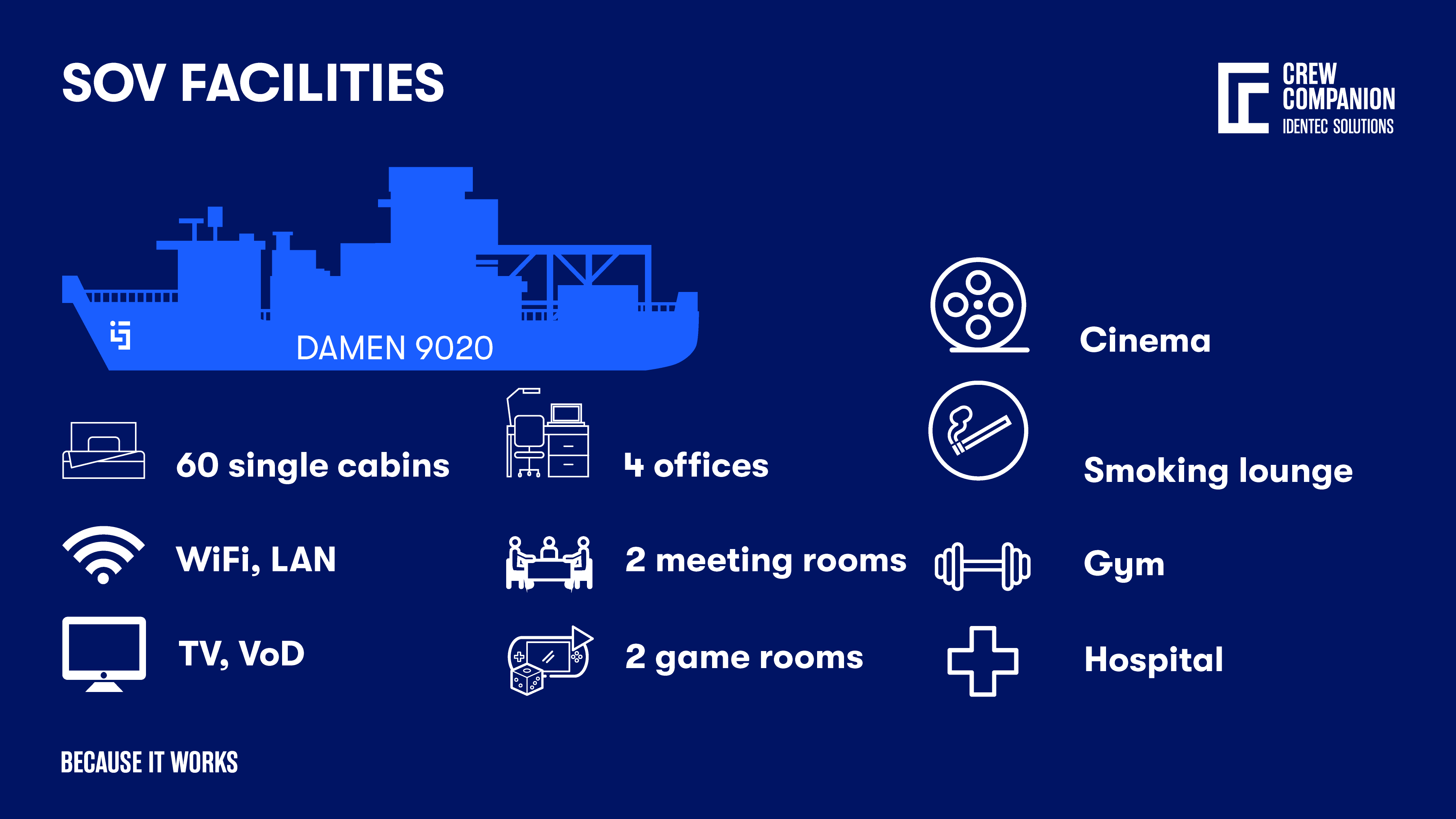

By investing in dedicated support vessels with accommodation facilities, offshore operators address the logistical complexities and provide a safe and secure environment for their crew. SOVs are equipped with modern amenities, such as comfortable living quarters, dining areas, and recreational spaces; they offer the crew a home away from home and act as floating hotels.

This ensures they can rest and recharge between their shifts, promoting their overall well-being and reducing fatigue-related risks. Moreover, these support vessels can also serve as a hub for various support services. From medical facilities to maintenance workshops, they provide a centralised location for essential operations. This eliminates the need for multiple trips to the shore or relying on external resources, saving time and ensuring prompt assistance in case of emergencies.

By eliminating the daily commute between shore and offshore, these floating hotels also contribute to a more sustainable approach to offshore operations: less fuel consumption and emissions help minimise the environmental footprint of crew transfer.

Walk-to-Work Gangways

One of the maritime industry's biggest issues is ensuring crew members' safety during offshore transfers. Due to the inherent risks, this is difficult to accomplish with traditional crew transfer methods, and therefore, offshore companies explore alternatives for their transfers. The Walk-to-Work concept is a promising candidate.

Specially designed gangways revolutionise offshore transfers by providing a safe and efficient means for crew members to traverse between the vessel and the offshore installation. Such gangways offer non-slip surfaces, sturdy handrails, and state-of-the-art fall protection systems, and greatly mitigate the risks associated with conventional transfers.

The Walk-to-Work system also addresses the potential dangers of falling objects and equipment malfunctions and minimises the likelihood of accidents during hoisting operations.

These systems also eliminate the need for personnel baskets and crane transfers; crew members are no longer exposed to the uncertainties and hazards that come with these outdated methods.

Moreover, these gangways offer enhanced stability and security, even in challenging weather conditions. Their robust design and engineering ensure a steady and reliable connection between the vessel and the offshore installation, allowing crew members to carry out their tasks with confidence and peace of mind.

Walk-to-Work: What is the benefit?

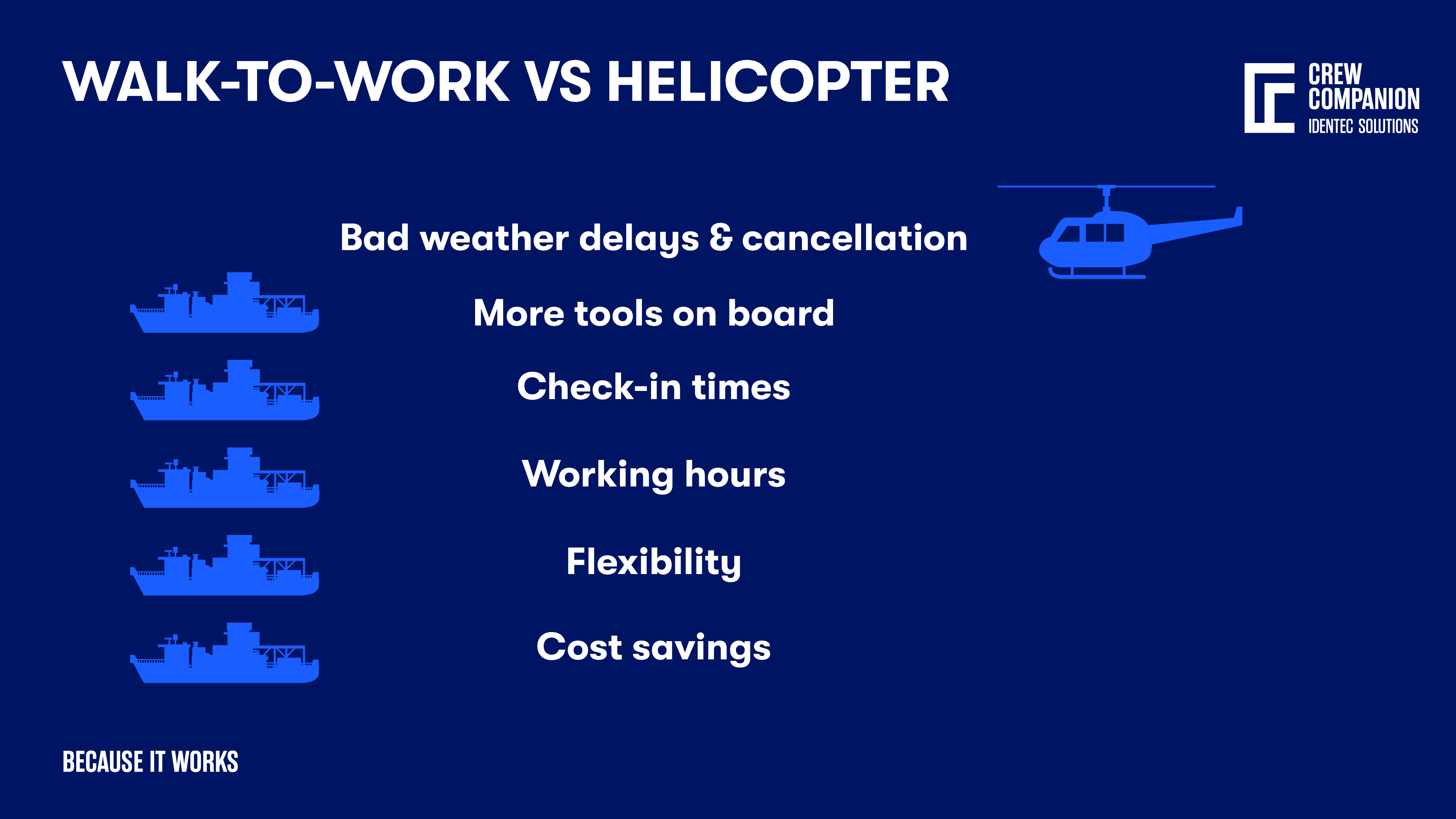

The integration of Walk-to-Work systems into offshore operations has completely transformed the way personnel move between offshore installations and support vessels. Historically, helicopters were the favourable method for personnel transportation, both to and from offshore facilities.

But as shown above, gangway systems have significantly reduced the risks associated with helicopter operations while also boosting work efficiency and minimising downtime.

Safety is the top priority in the offshore industry, and these solutions have taken it up a notch compared to traditional transfer methods. By eliminating the reliance on helicopter flights, which are susceptible to adverse weather conditions and mechanical failures, personnel transfers become inherently safer. Additionally, Walk-to-Work often uses advanced motion-compensated gangways that create a stable and secure connection between the vessel and the offshore installation, thus reducing the risk of slips, trips, and falls during transfers.

Walk-to-Work systems streamline personnel transfers, resulting in enhanced operational efficiency. Instead of relying on scheduled helicopter flights, crew members can transfer more frequently, facilitating smoother crew rotations and speeding up project execution. This heightened efficiency directly translates into cost savings and improved resource utilisation.

Helicopter operations are often limited by adverse weather conditions, causing delays and potential safety hazards. In contrast, walk-to-work gangways are designed to operate in a broader range of weather conditions, expanding the workability windows and ensuring continuous operations even in challenging environments.

Regardless, if you think about wind farms, fixed platforms, or floating structures, a Walk-to-Work solution, with its versatility, can be adapted to many different types of offshore installations. Usually, they have a modular design, allowing for easy installation and integration, making them suitable for both new projects and retrofitting existing facilities or vessels.

On the other hand, operations which include Walk-to-Work have their limitations when it comes to sea state conditions. To tackle this challenge, detailed site-specific assessments are crucial during the planning phase. By identifying optimal transfer windows and using advanced weather forecasting technologies, operators can minimise the impact of adverse sea conditions and ensure safe and efficient personnel transfers.

Also, proper training for both offshore personnel and vessel crew is vital for the successful integration of Walk-to-Work systems. Training should cover emergency procedures, gangway operations, and safety protocols to ensure that everyone involved can respond effectively to potential incidents.

And last, but not least, continuous technological advancements are essential to keep up with evolving industry standards and safety requirements. Regular inspections, maintenance, and upgrades of the systems are necessary to guarantee optimal performance and compliance with safety regulations.

Walk to Work: This is the way

One key area of focus is motion compensation technology, which plays a vital role in stabilising the gangway connection between the vessel and the offshore platform. Moving forward, we can expect advancements in motion compensation capabilities, providing even greater stability during personnel transfers. Utilising advanced predictive algorithms, real-time data processing, and adaptive control systems will help mitigate the impact of vessel motions, ensuring safe and comfortable transfers in a wider range of sea conditions.

The offshore industry is steadily embracing automation and autonomous technologies. In the future, we anticipate the development of autonomous Walk-to-Work systems that reduce the need for human intervention during transfers. Imagine unmanned gangways and remotely operated vessels, optimising safety by minimising human exposure to hazardous conditions. Moreover, these autonomous systems can operate around the clock, further improving operational efficiency (read more about worker safety monitoring).

Augmented Reality (AR) and Virtual Reality (VR) technologies hold great promise for enhancing training programs and real-time decision-making during crew transfer operations. By integrating AR into crew training, personnel can simulate various scenarios, practising emergency procedures and safety protocols in a virtual environment. During live Walk-to-Work operations, AR and VR can provide real-time data overlays, assisting crew members in assessing environmental conditions and making informed decisions for safe transfers.

Sustainability and environmental consciousness are becoming increasingly vital in the offshore industry, and Walk-to-Work systems are no exception. Expect a push towards eco-friendly solutions, such as the adoption of electric or hybrid propulsion systems for SOV vessels, reducing emissions and minimising the environmental impact of operations. Additionally, efforts to use recyclable materials and optimise energy consumption in gangway designs will contribute to a greener offshore sector.

As the transition to renewable energy gains momentum, Walk-to-Work systems will play a significant role in the maintenance and servicing of offshore wind farms and other renewable energy installations. The integration between those systems and renewable energy platforms will become more seamless, catering to the specific needs of these structures. This synergy will foster safer and more sustainable offshore operations, supporting the industry's commitment to a low-carbon future.

Incorporating big data and predictive analytics into Walk-to-Work systems will enable better decision-making and maintenance planning. By collecting and analysing data from various sensors and monitoring systems, operators can anticipate maintenance requirements, identify potential issues, and optimise crew rotations based on environmental conditions. This data-driven approach will maximise the system's efficiency, reduce downtime, and enhance safety.

As a result, the systems will continue to revolutionise the offshore industry, providing safer and more efficient personnel transfers in the years to come.

FAQS

What is a walk-to-work ship?

These innovative ships are specifically designed to provide a secure and reliable means of reaching offshore structures, ensuring the safety of workers even in challenging weather conditions. With their advanced features, these vessels greatly enhance access to platforms in both the wind and oil and gas industries, allowing operations to continue seamlessly. Equipped with state-of-the-art active heave-compensated gangways, these ships are able to adapt and compensate for the motion of the ocean, providing a stable and secure passage for personnel and equipment. This cutting-edge technology ensures that workers can access offshore structures, even in adverse weather, without compromising their safety or the efficiency of operations.

What type of vessel is used in offshore wind?

SOV (Service Operation Vessel), CSOV (Construction Service Operation Vessel), ISV (Installation Support Vessel), and Construction Support Vessels belong to specialised W2W vessels, or Multi-Purpose Support Vessels, and have become essential players in the offshore wind industry, serving critical roles in maintenance, construction, and installation processes.

In the past, these vessels serviced primarily the oil and gas industry. However, with the remarkable expansion of the renewable energy sector, SOVs are in high demand in offshore wind farms.

Takeaway

Walk-to-Work has truly revolutionised offshore operations, offering an efficient and ground-breaking solution to ensure the safety and well-being of personnel. The Industry has completely transformed the way it operates, due to the ability to securely transfer workers to and from offshore platforms. Thanks to their focus on safety and providing a controlled means of transfer, Walk to Work systems have significantly reduced the risk of accidents and injuries, making them a game-changer for the industry.

Yet, introducing a Walk-to-Work solution calls for thoughtful planning and a dedicated adherence to regulations. Companies need to consider several critical factors, such as weather conditions, system capacity, and the specific requirements of their offshore workforce. By conducting thorough analyses and carefully addressing these aspects, organisations can smoothly integrate these systems and guarantee the safety and efficiency of their operations.

In addition to that, continuous maintenance and improvement are absolutely crucial to ensure those systems operate at their best. Regular inspections, repairs, and upgrades are essential to address any issues and maintain the systems in top-notch condition. By investing in their maintenance, companies can extend their lifespan and make the safety of their personnel a top priority in the long run.

Looking ahead, the future of Walk-to-Work looks incredibly promising, thanks to advancing technology. We can expect the integration of innovative features like autonomous vessels, advanced monitoring systems, and virtual reality training, which will take the efficiency and safety of offshore operations to new heights. Moreover, increased collaboration and knowledge sharing within the industry will further enhance the development and implementation of these systems, creating a safer and more productive offshore environment for everyone involved. The future indeed looks bright for Walk-to-Work!

Dive deeper into one of our core topics: Personnel on board

Sources:

(1) Salzmann, D. Cerda, Prezzi, J., ten Haaf, S., and S. Groenteman. "Walk To Work Offshore Using Motion Compensated Gangways." Paper presented at the OTC Brasil, Rio de Janeiro, Brazil, October 2015. doi: https://doi.org/10.4043/26197-MS

Note: This article was updated on the 6th of August 2025. This article was partly created with the assistance of artificial intelligence to support drafting.

Author

Michal Wozniakowski-Zehenter, Marketing Manager

Michal Wozniakowski-Zehenter is an experienced marketing and project management professional. He spent most of his career on projects with a strong focus on digital marketing and event management. He is a very active voice representing offshore and mining industries through social media channels. Michal writes mainly about offshore oil and gas, renewable energy, mining and tunnelling. Compiling and sharing the knowledge within industries is one of his goals.