101 Reefer Container: Everything you need to know

| Written by Mark Buzinkay

No video selected

Select a video type in the sidebar.

Table of contents:

- What Is a Reefer Container?

- How Does a Reefer Container Work?

- Components Of a Reefer Shipping Container

- Reefer Container Dimensions and Specifications

- Stowing a Reefer Container Properly

- Thermal Shields: Guarding Goods Against Temperature Extremes

- Takeaway

- Glossary

"As the logistics landscape evolves, the efficiency of reefer containers remains paramount for maintaining the integrity of temperature-sensitive cargo."

Joel Reyes, Head of Professional Services Americas

Reefer containers play a vital role in the global supply chain. They carry food, medicines, and electronics wherever needed. Designed to carry such temperature-sensitive goods, reefers are undoubtedly one of the essential container types out there. The pharmaceutical reefer container market alone is valued at USD 4353.6 Million in 2025 and is projected to reach USD 12125.78 Million by 2033, with a CAGR of 13.66%. (1)

WHAT IS A REEFER CONTAINER?

Reefer container is short for the refrigerated container, also abbreviated as RF container. A refrigerated container is a shipping container that remains its cargo at a regulated, cool temperature. A reefer usually works at a temperature range of -30°C and +30°C and handles frozen, chilled, or cold goods. Special refrigerated containers (super freezers) can maintain a temperature down to -70° C (further reading: Reefer operations - How to optimize efficiency and safety).

Usually, a reefer has his refrigeration unit. This unit needs power to generate chilled airflow, maintaining the desired temperature and humidity.

Learn how real-time reefer information impacts safety and productivity in container terminals.

HOW DOES A REEFER CONTAINER WORK?

As the refrigeration of the container is done by air, airflow is the most vital part of a reefer container. The generator blows cold air along the floor or side into the container on one side of the reefer. The floor is T-shaped and distributes the airflow below the cargo unobstructed. As a result, the cold air ascends and returns on top of the load on the other end of the reefer container. That said, a reefer container maintains the pre-cooled temperature of the cargo, but it cannot reduce the temperature of the cargo! In other words: a load of a reefer container has to be brought to the desired temperature before loading.

A generator provides the necessary power to create the airflow which is needed for the refrigeration unit to work. One type of reefer is connected to power sources (for instance, on vessels). Still, very sensitive cargo may need a backup power source when disconnected (for example, in a container terminal). The best idea is to equip a reefer with its genset. Gensets can be built directly into the container, which means that special chassis with gensets or other logistics arrangements for clip-on gensets are unnecessary.

Ventilation is another vital aspect of a refrigerated shipping container besides controlling temperature. Fruits, vegetables, and plants release C02, water, heat, and ethylene. Not removing these can spoil the cargo by causing uncontrolled ripening, ageing, and altering flavour. Therefore, reefers are kept ventilated by fresh air.

Additionally, humidity plays also an essential role in keeping cargo safe. A dehumidification setup maintains the correct levels of moisture in a reefer. Keep in mind that different cargo needs different humidity levels. Although some newer units can reach 50%, the standard is between 60% and 85% relative humidity (RH).

To control power (check: reefer plugs), temperature, C02 levels and humidity, microprocessors (data loggers) register and transmit data continuously with the help of remote modems. This device stores all data, such as supply air and return air temperature, remote cargo probe temperatures, defrost activity, changes to the setpoint, power on and off time, etc.

Completing the technical reefer container functionalities, a built-in drainage system gets rid of excess water in case of water accumulation. In addition, their design prevents water or insects from getting into the container.

(Further reading: Reefer productivity)

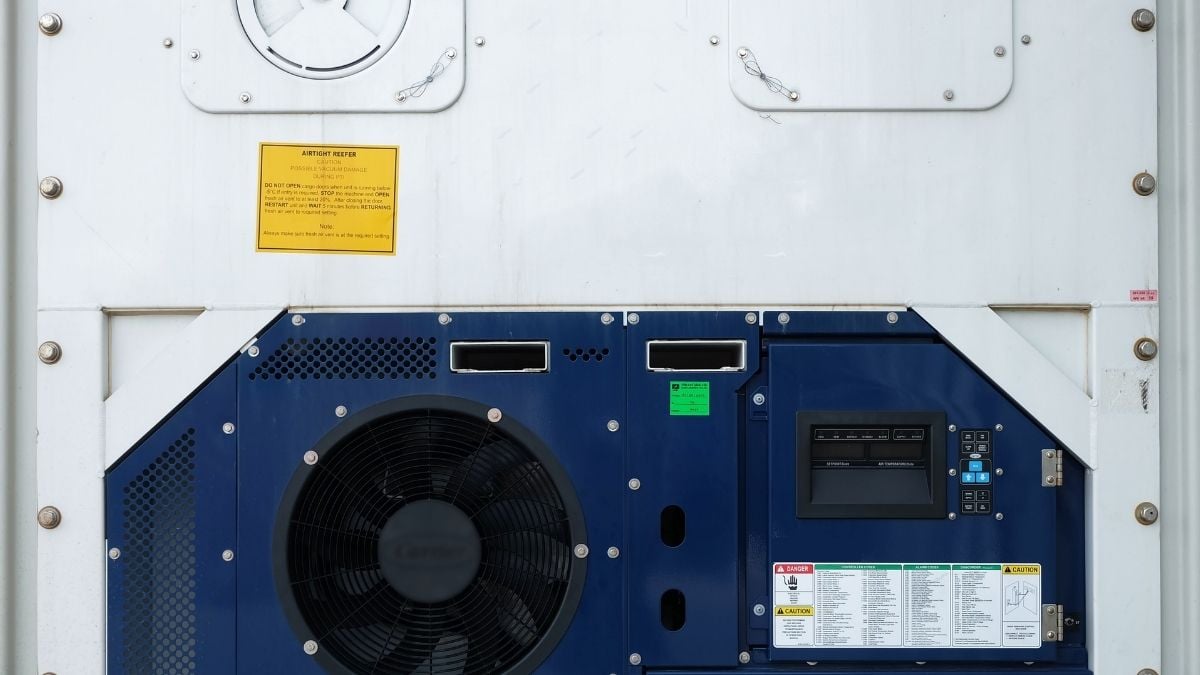

COMPONENTS OF A REEFER SHIPPING CONTAINER

The main components (besides the genset) include:

- Interior fans: Interior fans are installed inside the refrigerated container and help spread air to promote adequate temperature control and stability.

- Control unit: The control unit sets and adjusts the internal climate of the reefer container, including the temperature, alarm conditions, and in some cases, ventilation and humidity levels.

- Fresh air vent: The fresh air vent hole lets air enter from outside, and any gases from the container, such as fruit-ripening ethylene gas, can leave.

- Unit evaporator: Excess moisture in a reefer can harm products, quicken food spoilage and break down packaging, leaving contents vulnerable. The unit evaporator helps preserve the humidity inside the container. The reefer unit evaporator can either heat or cool the air that circulates past it from the fan. Heating capacity uses either hot gas heat or electrical heating elements.

- Condenser: Air-cooled models pull cooled air from the top of the container and discharge it under the cargo, pushing the air to the back doors before it convects naturally and rises, flowing back over the load to the return air inlet on the reefer unit. Because air moves under the cargo, proper loading and covering as much of the floor as possible is critical to prevent a “chimney” effect and short cycling.

- Voltage transformers: Dual voltage transformers are also an option with some containers, allowing operation on voltages down to 200V.

A variety of reefer shipping containers may have additional features such as remote reefer monitoring or specially constructed frames to prevent explosion when transporting sensitive materials.

REEFER CONTAINER DIMENSIONS AND SPECIFICATIONS

Reefer containers come in different measures and specifications. Most of them are manufactured according to the International Organization for Standardization (ISO) standards. Nevertheless, some reefer specifications may vary depending on the manufacturer and container age.

| Measurement | 20ft Reefer | 40ft Reefer | 40 High Cube Reefer |

| Internal length | 17.9 ft / 5.44 m | 37.9 ft / 11.56 m | 38.0 ft / 11.59 m |

| Internal width | 7.5 ft / 2.29 m | 7.5 ft / 2.28 m | 7.5 ft / 2.285 m |

| Internal height | 7.5 ft / 2.27 m | 7.4 ft / 2.25 m | 7.9 ft / 2.40 m |

| Tare weight | 3,080 kg / 6,790 lbs | 4,800 kg / 10,584 lbs | 4,600 kg / 9,880 lbs |

| Payload capacity | 27,400 kg / 60,417 lbs | 27,700 kg / 61,079 lbs | 29,500 kg / 65,036 lbs |

| Cubic capacity | 999 cu ft / 28.3 m³ | 2,093.3 cu ft / 59.3 m³ | 2,366 cu ft / 67.0 m³ |

STOWING A REEFER CONTAINER PROPERLY

A reefer may have a particular cubic and payload capacity. Still, due to airflow, a reefer container cannot be packed to utilize all the space like a dry container.

Inside a refrigerated container, goods should not hang over pallets to allow proper air movement. The boxes should have vent holes to enable vertical airflow from the bottom of the container. Align all vents in boxes to maintain air moving as smoothly as possible. Allow air to move between the roof and the top of the boxes.

Different goods have different needs; they must be stowed differently to ensure constant airflow. With chilled cargo, air must flow through it as it will remove heat and gasses. Ventilation is vital here. Frozen goods must be stacked next to each other to have no gaps between the cargo and the walls. This blocking of airflow helps the foods keep a low temperature. Otherwise, the cargo's texture, taste, and quality may get altered.

As mentioned above, it is crucial to pre-cool goods before they are loaded into the reefer container. To do so, it's optimal to use a dedicated cooling facility as it is more feasible and energy-efficient to pre-cool the goods than to pre-cool the reefer. If you pre-cool the reefer container, warm and moist air from outside will enter the reefer and cause excess development of moisture and unnecessary defrost cycles, further reducing the ability of the reefer container to cool the product efficiently after loading.

Learn how automated monitoring of refrigerated reefer containers results in fewer claims.

Thermal Shields: Guarding Goods Against Temperature Extremes

Anyone purchasing refrigerated containers must know the features that ensure optimal cargo conditions. One of the most important aspects to consider is the quality of insulation.

High-quality insulation is a must. It helps maintain interior conditions by preventing outside temperatures from affecting the environment. The higher the R-value, the better the insulation performance and, thus, the energy efficiency.

The "R" in the R-value stands for "resistance." It quantifies a material's ability to resist heat transfer and is affected by factors such as material type, thickness, and density. The value is defined as the ratio of the temperature difference (in degrees Fahrenheit) across the material to the heat transfer rate (in BTUs per hour).

BTU stands for British Thermal Unit, a unit of measurement for thermal energy. The unit represents the energy required to raise the temperature of one pound of water at sea level by one degree Fahrenheit.

Refrigerated container insulation is usually made of materials such as polyurethane foam or fibreglass, but the materials are often used in combination.

Polyurethane foam is known for its excellent thermal insulation properties. It can conform well to different shapes and sizes, while its lightweight and volume allow for compact designs. Polyurethane foam can be injected into doors, panels, and seals. It is often used in corner panels to effectively eliminate thermal bridges and thus improve overall performance.

Fiberglass also has excellent thermal insulation properties, and its corrosion resistance makes it ideal for harsh environments. The material is very durable and can withstand temperature fluctuations well. It is also lightweight and helps to keep fuel consumption low during transportation. Fiberglass can be shaped to suit individual designs.

Takeaway

Reefer containers are critical in the global supply chain, ensuring the safe transportation of temperature-sensitive goods like food, medicine, and electronics. These refrigerated containers maintain temperatures between -30°C to +30°C, relying on a generator to power airflow, which keeps cargo at a consistent pre-cooled temperature. Proper ventilation and humidity control prevent spoilage, while insulation quality is vital to energy efficiency. Reefer containers are equipped with microprocessors to monitor and log key data like temperature and humidity. Proper stowing techniques are essential to maintaining airflow and preserving the quality of different cargo types, ensuring efficient and safe transport.

Interested to learn everything about the Cold Chain and Reefer Management?

Discover the basics of Cold Chain logistics and download our free eBook "Inside The Box: Cold Chain and Reefer Management".

We published our eBook as an online version: Cold Chain and Reefer Management

Delve deeper into one of our core topics: Refrigerated containers

Glossary

A drainage system is a network of pipes and channels designed to remove excess water from an area. In reefer containers, the drainage system is crucial for expelling condensation and defrosting water, preventing water accumulation that could damage cargo or promote mould growth. Typically, reefer containers have four drain holes in the floor corners, connected to drain pipes. This system helps maintain optimal humidity levels and protects the cargo from water-related issues during transportation. (2)

Ethylene is a colourless, odourless gas naturally produced by fruits and vegetables as a ripening hormone. In the cold chain context, ethylene management is crucial as it can accelerate the ripening and spoilage of produce, even at low temperatures. Absorbers and scrubbers are used in storage and transportation to remove excess ethylene, extending shelf life and maintaining quality. Proper ethylene control is essential for preserving freshness, reducing waste, and optimising cold chain efficiency for climacteric fruits and other sensitive produce. (3)

Sources:

(2) Lukasse, L.J.S. and Paillart, M.J.M. (2013): Drain holes in reefer containers and the conflicting interests of controlled atmosphere and dehumidification. In: Proceedings of the 2nd IIR International Conference on Sustainability and the Cold Chain.

(3) Tokala, V.Y. and Mohammed, M. (2022): Cold Chain Management for the Fresh Produce Industry in the Developing World. Routledge.

Note: This article was updated on the 17th of September 2025.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.

Related Articles

Related Product