Why you need RFID for RTLS

| Written by Mark Buzinkay

A real-time location system (RTLS) allows you to locate and track assets. With this data at your disposal, you can also manage, analyse and leverage data improving and controlling processes in your production line.

In this post / whitepaper, we show you the technical composition and implementation of an RTLS system combined with RFID technology.

No video selected

Select a video type in the sidebar.

Table of contents:

- Do you need RFID for RTLS?

- RTLS RFID Hardware

- RTLS RFID Hardware Software

- RTLS RFID Integration

- Takeaway

- Glossary

The prerequisite for process optimisation is a deep understanding of the process itself. Otherwise, you will change a process without understanding the consequences. You also need to understand the central interdependencies within your process. If not, it is try-and-error field research on a big scale. Indeed, this can be an excellent approach to innovating products and services, but when you want to maintain quality, reduce scrap, and improve production length and costs, you need data. Data are like glasses: You can see the flow clearly, uncover bottlenecks, identify idle times, and spot unnecessary process steps. This is where RTLS comes into play: To make a process truly visible by creating data.

The global Real-Time Location System (RTLS) market is experiencing significant growth, with projections indicating an increase from approximately USD 5.2 billion in 2024 to around USD 16.2 billion by 2032, at a compound annual growth rate (CAGR) of 25.5%. (1)

Do you want to understand RTLS technology? Download our RTLS eBook, no registration needed!

Do you need RFID for RTLS?

RTLS needs two things to work: Technology (hardware and software) and assets that can be tracked. Assets can be everything, for example, vehicles, tools, merchandise or spare parts. As assets in a production line are material objects, they need a digital twin: a representation in the digital workflow. Tags attached to assets will convert them to digital objects and duplicate them - as physical objects in the production line and as immaterial objects in the process control software.

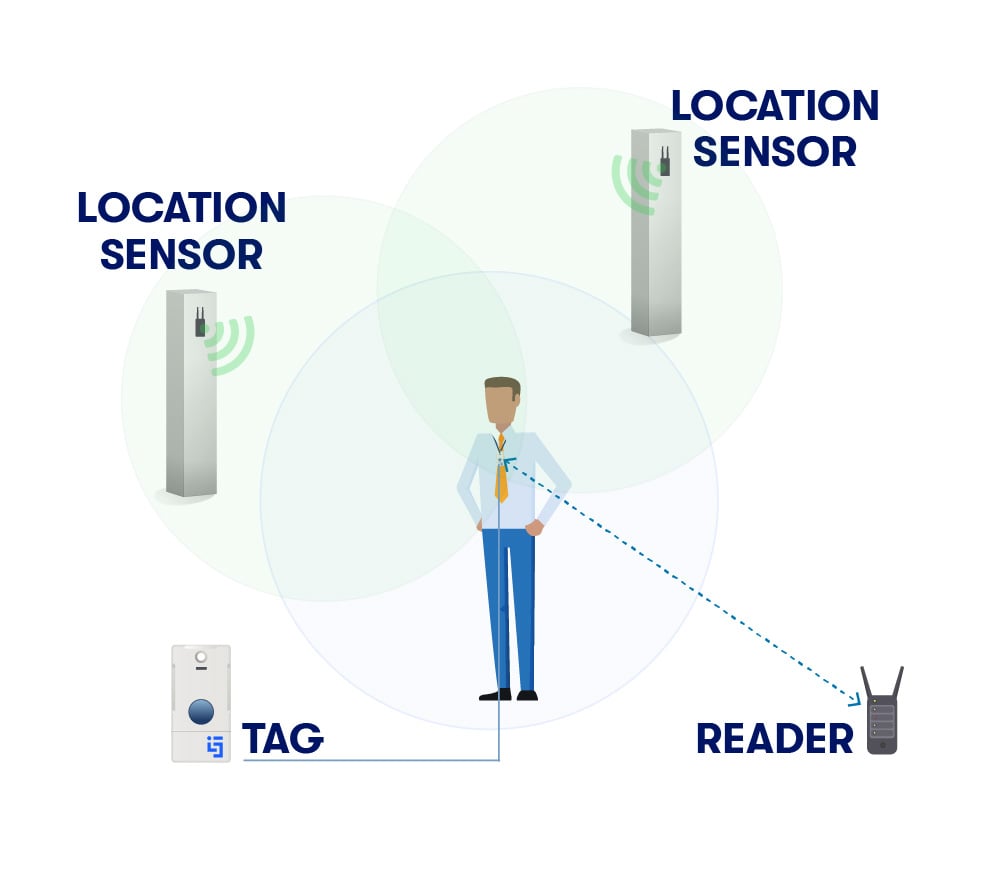

Tags are mobile devices that are enabled with location technology. A tag is usually small enough that it can be attached to assets or carried by people. Depending on the technology, a tag needs a specific reader to determine its current location of the tag. The reading device is a location sensor with a known position. For example, the GPS satellites are the location sensors, and signals from these satellites determine the location of tags (GPS receivers).

A location engine uses the location signals to compute the tag's current location, which is the core of the RTLS software. It will transfer this data to middleware and applications. The middleware is the connection between the hardware (tags and readers), the location engine and the business applications. Business applications will request data from the middleware when they need it. This is the interface users see and interact with.

Many technologies can be used to create RTLS, such as infrared, Bluetooth, Wi-Fi, RFID, Ultra Wideband, GPS, Cellular, and many more. In this whitepaper, we focus on RFID for the following reasons:

- RFID is an established and proven technology

- RFID is very reliable

- RFID can be used outdoors and indoors

- RFID works in most environments

RFID stands for Radio Frequency Identification and uses radio signals to "communicate" between tag and reader. Active tags have their own power source (battery) and send signals without being prompted with a range of up to several hundred meters. Battery life is essential and should last for years, depending on the tags' task. For example, tags can be used to measure temperature, motion, humidity, pesticides, etc. (1)

RTLS RFID HARDWARE

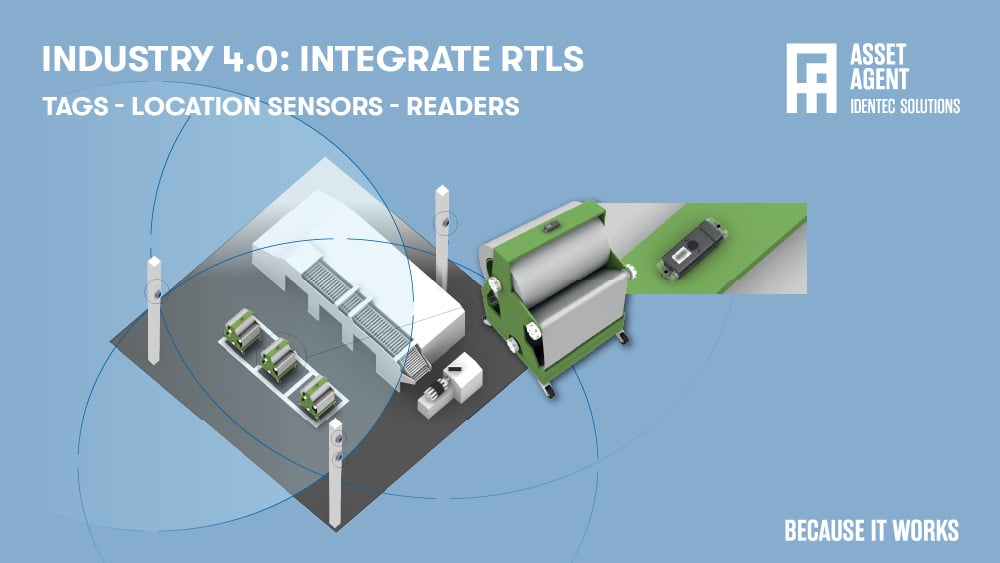

We mentioned that RFID works as a tag and reader setup from a hardware perspective. So, let's have a closer look at RFID hardware for RTLS.

Tags

Tags' primary purpose is the identification of material objects. Active tags, unlike passive or semi-passive tags, contain an onboard radio (transmitter or transceiver) and are typically powered by an internal battery. They usually have a long range, communicate without being prompted and can be located in real-time. Battery life depends on the usage and how they send (how often). Batteries in harsh environments should last several years because they are not suitable to exchange batteries (breaking seals) or unreliable enough to recharge them (e.g. by solar power). Tags must withstand the conditions of their environment (water, dust, temperature, humidity, ...)

Location sensors

Location sensors are an essential part of RTLS. They create the locating "frame" or coordinates for positioning. You need several location sensors (3 at a minimum) to determine the position of a tag within the range of the tag. The XYZ coordinates of each location sensor are mapped into the software.

Sometimes, Close Range Identification of tags substitutes for location sensors. This type of sensor (let's call it "markers") has an adjustable, short radius. Therefore, its ID is transmitted to any tag nearby (e.g. a machine equipped with a close-range identification reader transmits its ID to a tag mounted on a container that was moved to that machine). In this way, the position of a tag is determined by the proximity to a Close Range Identification marker.

Readers

The reader is the core of the operation in that it transmits and receives radio waves to communicate with an active RFID tag. In doing so, it typically uses one or more antennas, along with the abovementioned software application. For the most part, RFID readers come as a fixed model. Fixed readers remain in one location, usually mounted on walls, into portals, or on another suitable structure for the read-zone. Because they generally need external antennas to read active tags accurately, they incorporate external ports for connecting one or more additional antennas, depending on the required coverage area.

Mobile RFID readers are compact, handheld devices in which the antenna is either integrated or externally attached. Known for their flexibility, they can be mounted or carried anywhere while still communicating with a host computer.

As mentioned, all readers need a connection to a server receiving data and manipulating it with the help of the middleware.

RTLS RFID SOFTWARE

In general, an active RFID tag will send out signals and, if in range, detect location sensors. Then, the tag calculates the distance to each location sensor based on the readings. Once the position data is defined, the information is broadcast to the fixed or mobile readers. A built-in motion sensor, user request, or timed intervals can trigger the positioning event.

In production processes, close-range identification uses a short-range marker to detect tags in close proximity. A marker constantly transmits an ID, and as soon as an RTLS tag detects the vicinity of a close-range marker, the tag will transmit its ID and the ID of the close-range marker to an RFID reader, enabling location detection of the tag (see also: RFID location tracking).

Readers will transmit all data to middleware, connecting software applications and allowing them to communicate with each other and exchange data. It makes business applications independent of RTLS technology. Middleware enables applications to configure, monitor, deploy, and issue commands directly to the location sensors and tags through a common interface. It also filters and routes events of tags, stores them and consolidates data (e.g., the same events received for the same tag). Middleware also processes and manages business rules for additional applications.

In an RTLS, an application is the computer software that interacts with the RTLS middleware to solve the problems challenging end users, such as enabling users to achieve the tasks they wish to perform or solve issues for another application program.

RTLS RFID INTEGRATION

As your business software environment knows dozens of applications for planning, managing and monitoring assets, processes and people, integrating RTLS is another additional challenge. Thanks to the middleware and business application layer of RTLS, that's easier than it may sound. Whether you integrate RTLS RFID or another technology into your existing software stack doesn't matter. The middleware converts signals and data and transfers them to your other applications. In the case of RTLS, it is about integrating real-time visibility seamlessly into business practices.

Integration is usually achieved through some form of data connection: transport, transformation and routing. Transport involves protocols and software to move data. Data transformation converts data from one format to another and includes mapping data elements from source to destination. Finally, data routing describes the real-time communication (e.g. an RTLS location event) from one application to another - synchronously or asynchronously.

Typically, a solution should have APIs and flexible architecture when performing an RTLS integration.

Effective RTLS integration can result in many significant benefits, such as streamlining inefficient procedures, eliminating redundant data, adding new business value, increasing scalability, and unifying device management.

Streamlining inefficient procedures

Procedures that require users to switch among applications are more error-prone and inefficient. Integration can simplify business processes; for instance, an RTLS solution is installed to locate assets, and you combine it with existing material management software. With integration, you can access historical data from the RTLS asset-locating application without maintaining different lists.

Redundant data

Storing the same data in multiple databases increases hardware, software, backup needs, and administration costs. It also introduces inefficiencies, risks of data corruption and potential human errors.

Business value

RTLS integration is the most cost-effective way to add new business value to the enterprise through innovation.

Like any other integration, integrating an RTLS is a complex task. It's a project based on integration flows, budgets, and staffing, so you need to do an integration audit before you start. This includes an analysis of your existing and planned interfaces, systems and workflows. Following, you define an integration implementation strategy, including an estimate of costs (architecture, integration and operating costs), identifying debugging and testing tools and understanding the significant integration challenges.

TAKEAWAY

RTLS based on RFID offers cost-effective, reliable technology for real-time visibility of physical assets and people. But without integration, the results are isolated functionality, redundant manual activities and inefficiencies - the exact opposite of your RTLS business case. An RFID RTLS integration project needs an audit and a strategy, but mostly the experience of a knowledgeable person or team who implements and integrates hardware and software into the existing enterprise software stack (read also about the RFID - RTLS success story at VW Bratislava).

Extended reading: Real-time locating system and industry 4.0

Glossary

Ultra Wideband (UWB) is a wireless communication technology that uses a wide spectrum of frequencies to transmit data at short ranges with high accuracy. It enables precise location tracking, low latency, and secure communication, making it ideal for applications like indoor positioning, smart devices, automotive systems, and IoT. UWB’s ability to measure distance with centimeter-level precision sets it apart from other wireless technologies. (3)

Sources:

(1) https://www.marketsandmarkets.com/ResearchInsight/real-time-location-systems-market-size.asp

(2) D. -j. Park, Y. -b. Choi and K. -c. Nam, "RFID-Based RTLS for Improvement of Operation System in Container Terminals," 2006 Asia-Pacific Conference on Communications, Busan, Korea (South), 2006, pp. 1-5, doi: 10.1109/APCC.2006.255837

(3) Gezici, S. (2005). Ultra-Wideband Positioning Systems: Theoretical Limits and Practical Implementations. Cambridge University Press.

Note: This article was updated on the 31st of July 2025. This article was partly created with the assistance of artificial intelligence to support drafting.

Author

Mark Buzinkay, Head of Marketing

Mark Buzinkay holds a PhD in Virtual Anthropology, a Master in Business Administration (Telecommunications Mgmt), a Master of Science in Information Management and a Master of Arts in History, Sociology and Philosophy. Mark spent most of his professional career developing and creating business ideas - from a marketing, organisational and process point of view. He is fascinated by the digital transformation of industries, especially manufacturing and logistics. Mark writes mainly about Industry 4.0, maritime logistics, process and change management, innovations onshore and offshore, and the digital transformation in general.

Related Articles

Related Product