RTLS 101: What is it and where to use it

| Written by Christian Aadal

No video selected

Select a video type in the sidebar.

Table of contents:

- What is RTLS?

- Location models

- Understanding the technologies

- RTLS: Grasping the concept of tags

- Where to use RTLS?

- FAQs

- Takeaway

- Glossary

What is RTLS?

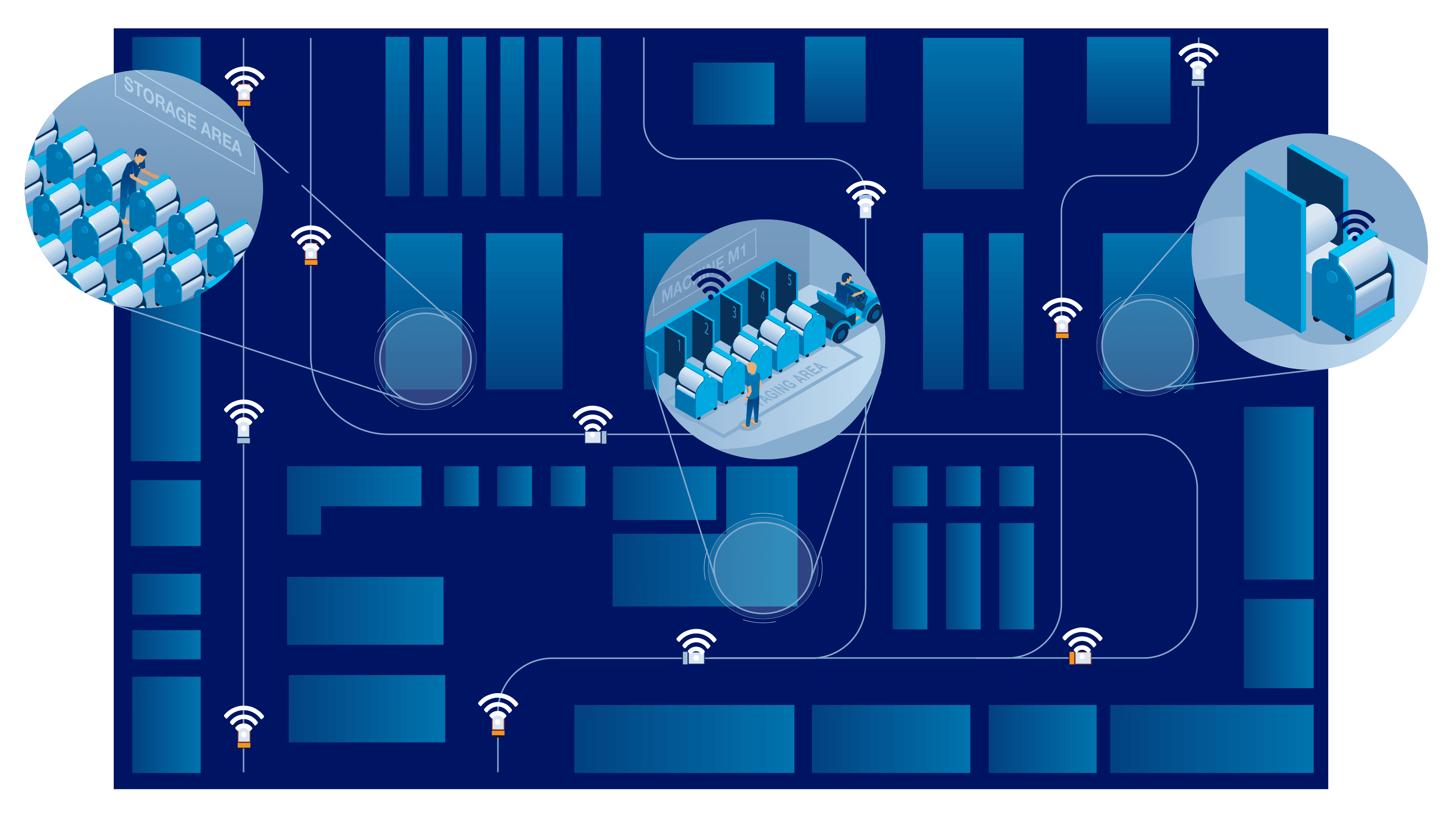

A Real-time Location System (RTLS) allows you to identify, track, oversee, examine, utilize, and otherwise harness the data about the whereabouts of assets or individuals. Picture the capability to monitor individuals and assets on a local, national, or even international scale. Merchants, armed forces, police, emergency responders, medical sectors, educational institutions, and virtually every industry - even domestic settings - can all gain, or already benefit, from employing RTLS solutions.

Location denotes where an object or person is, well, situated. With a Real-time Location System (or RTLS), you pinpoint and monitor individuals and assets by linking a tag, a compact wireless gadget, to each entity or person. Assets refer to things like computers, apparatus, and heavy machinery. For instance, you might affix a tag to a vehicle (an asset) to track its position within your facility (read also our article about RTLS asset tracking); or you might have an identification card, allowing someone to find you inside a structure.

To pinpoint individuals and assets instantaneously, an RTLS persistently observes the tag's positions. Subsequently, the RTLS conveys this locational data to software that processes and utilizes this information. Here are a handful of methods to employ RTLS tags to identify individuals and assets: Fasten tags to PCs, equipment, and transport vehicles; mandate individuals to possess tags (like ID cards, bracelets, anklets, clip-ons) or integrate tags into gadgets people already have, such as mobile phones.

Location models utilised by RTLS

When you're keen to discern the tangible location of an asset or individual, based on your requisites, you might desire to know the absolute location, relative location, or symbolic location. The absolute location refers to the exact coordinates (like latitude, longitude, and elevation). Relative location denotes the span in three dimensions in relation to a stationary point. Symbolic location signifies being in a designated zone like a safety chamber or cafeteria.

To cater to the demands of diverse applications, be it pinpoint location or broader room-level location, several RTLS solutions convey the position of tags in one of these manners:

Presence-oriented locating (an individual entered the premises), room-level locating (an individual accessed a particular chamber within the structure), sub-room-level locating (an individual is positioned at a distinct area within a chamber), choke point locating (an individual passed by an ingress or egress point of a structure or chamber and proceeds in a certain trajectory), proximity-based locating (an individual is near another tag), and precise locating (an individual is identified at a specific spot within the premises).

Learn more about it in our whitepaper 101 Smart Factory RTLS - or download our complete RTLS eBook (no registration needed).

The location concept will determine which technology is best suited for a specific business solution. In most cases, the more RTLS reference points that are installed, the better the location accuracy - within the limits of the selected technology. In general, the location of a transponder can be detected either by passing objects or by triangulation. The first possibility uses gates or choke points to monitor the flow of tags and with the help of directional antennas, the direction of the movement is received. In this case, you know if an object is still in the room or not, when it entered or left and where it went. The second possibility is to pinpoint the position of a transponder by triangulation (or other methods of calculating the position), using several readers that receive the transponder signal. The accuracy of the computed location depends on the technology, and the surroundings of the transponder and readers: walls, furniture, or various materials (like metal) can distort the estimated range.

Do you want to learn more about why a legacy process may be a real challenge for improvement?

Understanding the foundational technologies of RTLS

Numerous systems and innovations have been crafted over time by scholars and business enterprises to pinpoint the location of individuals, machinery, and other valuables. Nowadays, an RTLS can be implemented using illumination, visual cameras, infrared, acoustics, ultrasonic waves, Bluetooth, Wi-Fi, radio frequency identification (RFID), ZigBee, Ultra Wideband, GPS, and Cellular, among other technologies (see also: RTLS chip).

Various technologies employ distinct methods, and each method addresses a somewhat different challenge or caters to different uses. These systems differ in several aspects, like the physical mechanisms used for pinpointing location, the design of the tag and location detectors, energy needs, distance, suitability for indoor versus outdoor, and temporal and spatial precision. Some technologies pinpoint location at a room's scale, some can only detect presence, and some can locate with high accuracy. Certain technologies excel outdoors, while some are specifically designed for indoor settings. Some are apt for a corporate setting, while others are ideal for a manufacturing backdrop. Some necessitate extra location detectors, while others utilize pre-existing facilities, like power or Wi-Fi, in a structure.

In certain setups, the tag whose position is being identified calculates its own coordinates (often referred to as tag self-determining); whereas in others, the tag's position is ascertained by identifying the location of a neighbouring tag (commonly known as tag indirect-determining).

However, all RTLS technologies converge on the shared objective of determining the location of valuables and individuals with the precision required by the use case, and each achieves this in its unique manner.

RTLS: Grasping the concept of tags

When many individuals think of an RTLS, their minds instantly go to the RTLS tags, which are the most visible elements of an RTLS that most individuals interact with. However, an RTLS encompasses much more than just tags. It also consists of location detectors, positioning technology and techniques, location engine software, intermediary software, and the user application. Each of these elements needs to be adaptable to cater to businesses with varied settings, diverse requirements, and distinct applications. For the moment, let's delve into RTLS tags.

An RTLS tag is a compact gadget equipped with location-based technology. These tags can be used to pinpoint both assets and the individuals who possess them. Tags should be diminutive enough to be affixed to assets or to be held by individuals.

When you fasten a tag to assets, like vehicles, you usually adhere or bolt the tag onto the asset. At times, some opt to integrate the tag within assets. The positioning of assets is essentially the positioning of these tags. If the tag gets detached from the asset, the asset's tracking becomes impossible.

Depending on the tag's mode of communication with the rest of the RTLS, tags are categorized as passive, semi-passive, or active.

Passive tags are generally passive radio frequency identification (RFID) tags. A standard passive RFID setup comprises tags (or responders) and interrogators (or transceivers or scanners). The interrogator emits a radio wave that's picked up by the passive tags situated in the RF (radio frequency) zone of the interrogator. Tags capture the wave through their antennae and then relay their saved information.

Semi-passive tags (or battery-assisted passive tags) bear a resemblance to passive tags. They don't commence any communication, must be within the RF zone of the interrogator to be detected, and relay data to the interrogator using the identical backscatter method as passive tags. Nonetheless, semi-passive tags possess a minor battery. This battery primarily serves to either track environmental factors or to provide an extended range and dependability compared to passive tags. It's crucial to note that the battery in semi-passive tags doesn't produce RF energy.

Active tags, in contrast to passive or semi-passive tags, house an internal radio and are generally powered by an inbuilt battery. Owing to their internal radio, they often have an extended range and can communicate without external triggers. For this reason, these tags can be pinpointed in real-time, perhaps every couple of seconds; however, the lifespan of the battery is heavily reliant on its usage. If you aim to attach tags to mobile projectors to ascertain their whereabouts, you'd prefer these tags to broadcast only once the projector ceases movement. In this manner, you're always informed of the projector's last known location. Conversely, if you also wish to use the tags to not merely determine the position of projectors but also to receive a notification if a projector exits the premises, you'd desire this tag to broadcast continuously at rapid intervals, enabling real-time location tracking and immediate responsive actions. Such tags are typically bulkier and pricier than passive or semi-passive tags. Given that these tags contain batteries, battery longevity is a vital consideration.

Where to use RTLS?

The global Real-Time Location Systems (RTLS) market is experiencing significant growth. Estimates for 2024 suggest a market size of approximately $6.03 billion, with projections reaching $15.79 billion by 2029, reflecting a Compound Annual Growth Rate (CAGR) of 21.2% during this period. (1)

RTLS is a well-used concept throughout many different industries. Here is a list of different operational areas for real-time location systems:

- Identify the correct carrier to feed material into a processing machine

- Locate mobile equipment in a hospital to have it available

- Identify persons and grant access to a gated area

- Create automated jobs for lifting machines based on the identification of the objects

- Combine the identity of several items in a single location (e.g. pallets)

- Monitor muster zones and the whereabouts of personnel in case of an emergency

- Track the position of the parked vehicle after it leaves the production line

- Allow potential harmful operations in mines after all workforce has moved to a safe area

- Follow a product along the production line (in a conveyor or non-conveyor belt system)

Such scenarios will determine the technology and the set-up of the RTLS. Also with RTLS, there are limitations. Some technologies may not be suited in certain environments, for instance in hospitals where sensitive equipment is operating and lives are depending on them. This said every single case must be tested for a better understanding, especially the range of the signal and its strength. Placing readers in utility rooms or above doors between hospital wings to monitor assets is not a problem.

RTLS may consist of various technologies used at the same time, e.g. RFID, UWD and NFC combined in one system to perform different tasks. It is important therefore to make a proper choice to avoid wrong design decisions already at the early stages. To solve this problem a special methodology for RTLS design space exploration was developed. It consists of such steps as modelling, requirements specification, and verification into a single efficient process.

FAQ

What is RTLS and how does it work?

RTLS, or Real-time Location System, is a technology used to automatically identify and track the location of objects or people in real-time. It primarily operates by attaching tags to the items or individuals to be tracked, and these tags then communicate their position to a network of sensors. The system then processes this data to determine the precise location of each tagged item or person, often displayed on a software interface. The technology behind RTLS can vary, including radio frequency identification (RFID), Wi-Fi, infrared, and ultrasound, among others.

In what industries or applications is RTLS commonly used?

RTLS has a wide range of applications across various industries. Some of the most common include:

- Healthcare: Tracking patients, staff, and equipment in hospitals to improve patient care and operational efficiency.

- Manufacturing: Monitoring the location of tools, machinery, and assets to optimize production processes.

- Retail: Managing inventory, enhancing customer experiences by locating items quickly, and analyzing customer movement patterns.

- Logistics and Supply Chain: Tracking goods in real-time during transit or within warehouses.

- Security and Safety: Monitoring personnel in high-risk environments or tracking valuable assets to prevent theft.

What are the main differences between passive, semi-passive, and active RTLS tags?

The primary distinctions among these tags lie in their power sources and communication methods:

- Passive Tags: These do not have their power source. Instead, they derive energy from the interrogator's (or reader's) signal. When they come within range of an appropriate reader, they transmit their stored data back. They are typically cheaper and smaller but have a limited range.

- Semi-passive Tags (or Battery-assisted Passive Tags): These tags have a small battery to power onboard circuits, enhancing the tag's range and reliability. However, like passive tags, they still rely on the reader's signal to transmit data.

- Active Tags: These tags have their power source and an onboard radio transmitter, allowing them to broadcast their data over longer distances without needing to rely on a reader's signal. They are typically larger, more expensive, and have a finite battery life, but they offer real-time tracking capabilities.

Takeaway

Real-time Location System (RTLS) is a cutting-edge technology designed to automatically identify and track the location of assets or individuals in real-time. At its core, RTLS operates by attaching tags, which are compact wireless devices, to the items or people being monitored. These tags then communicate their position to a network of sensors, which is processed to determine the exact location. The applications of RTLS span across various sectors, including healthcare, manufacturing, retail, and logistics, among others. The technology behind RTLS can range from radio frequency identification (RFID) to Wi-Fi and infrared. Tags can be categorized as passive, semi-passive, or active based on their power sources and communication methods. While RTLS offers numerous benefits, it's essential to choose the right technology and setup for specific environments and needs to ensure optimal performance.

Dive deeper into one of our core topics: Real-time location systems in manufacturing and indoor logistics

Glossary

Technology refers to the application of scientific knowledge to create tools, systems, and processes that solve problems and improve human life. It encompasses fields such as engineering, computing, biotechnology, and artificial intelligence. Technology evolves continuously, shaping industries, communication, healthcare, and daily living. It enhances efficiency, connectivity, and innovation while also presenting ethical and societal challenges. (2)

Sources:

(1) https://www.marketsandmarkets.com/Market-Reports/real-time-location-systems-market-1322.html

(2) Arthur, W. B. (2009). The Nature of Technology: What It Is and How It Evolves. Free Press.

Note: This article was updated on the 12th of February 2025

Note: This article was updated on the 4th of August 2025.

Author

Christian Aadal, Product Manager

Christian Aadal holds a degree in Information & Communications Technology and Media and has several years of experience in the Telecom industry, working for some of the top names in the business. From a technical support engineer to project engineer, Global Product Manager - Asset Agent to sales, Christian prides himself on being able to understand industry needs with a focus on optimization, digitalization and security. His experience in the field gives him the ability to provide solutions for customers that can best meet their requirements and generate the value they are looking for. His passion is around Industry 5.0, where humans can bring out max efficiency in machines, and machines can bring out max efficiency of humans.