What is reefer monitoring? Why cold-chain visibility belongs in the IT strategy

| Written by Constance Stickler

No video selected

Select a video type in the sidebar.

Table of contents:

Reefer Monitoring Is a Shared Responsibility Across the Shipping Chain

Monitoring refrigerated containers is a shared responsibility that encompasses the entire transport route. Trucking companies look after the reefers on the way between producer and port, as well as between port and (wholesale) trade; container terminals monitor temperature and other parameters at the ports; and shipping companies assume responsibility during the sea voyage. Each participant contributes to the overall result – and each depends on the others to ensure product integrity.

Only in this way can the waste of food (1.3 billion metric tonnes or a loss of 1 trillion dollars per year today, and 2.1 billion metric tonnes or 1.5 trillion dollars expected by 2030 (1)) and pharmaceutical products (industry estimates range from 20 to 35 billion dollars loss annually, and 50% of vaccines discarded globally (2)) be countered.

Container terminals are among the most critical phases of the cold chain. Unloading, terminal handling, connection, transhipment, and gate movements entail physical and operational transitions that directly affect refrigerated containers.

For terminal IT, this means playing an active role in maintaining optimal conditions for refrigerated or frozen freight. Various data streams converge at the terminal: reefer monitoring, terminal systems, power supply infrastructure, and customer-facing platforms. When something goes wrong, these data streams are analysed in parallel to determine the cause and timing of the incident. Even if the root cause lies elsewhere, gaps or inconsistencies during the terminal's operation quickly bring the terminal under scrutiny.

Therefore, data from refrigerated container monitoring at the port is increasingly important as part of the chain of evidence demonstrating that the reefer was handled at the terminal in a timely and compliant manner. The data, therefore, forms the basis for customer trust, business success, and risk management.

Understanding this responsibility is the starting point. The next step is recognising that transparency alone is not enough. Ultimately, what matters is whether the monitoring data remains intact, up-to-date, and reliable during handovers—which leads us to the next question: Why is the transition from mere operational readiness to true data continuity indispensable today?

What is Reefer Monitoring? From Power-On Status to Data Continuity

Reefer transport perishable goods, some of which can spoil or become ineffective even with the slightest deviations in conditions. What is reefer monitoring observing? It checks and records temperature, humidity, power supply status, set-point adherence, ventilation rates, atmospheric conditions (such as oxygen and CO₂ levels), alarm events, and timestamps throughout the container’s journey to ensure cargo integrity and compliance. Maintaining the necessary conditions is only possible if all systems in the reefer are running reliably. And that requires electricity.

Thus, the first question concerning a newly arrived reefer at port is whether it will be reconnected to the power supply in a timely manner after being disconnected from the ship. However, the power status only indicates that power is (re)flowing; it is not proof that all parameters are correct. From a data perspective, "connected to power" is not a condition, but merely a prerequisite.

This is where the importance of data continuity becomes crucial. Continuous monitoring means not only capturing more data points, but also ensuring there are no blind spots during handovers. For a terminal, the most critical moments are often the least visible: unloading from the ship, connection to the terminal premises, transhipment, power outages, or brief disconnections during maintenance work. It is precisely at these moments that data gaps frequently occur – and the cargo risk increases.

From an IT architecture perspective, monitoring refrigerated containers is increasingly similar to that of other high-availability systems. It involves endpoints at the container level, communication layers within the terminal, backend platforms, and interfaces with external partners.

The operational teams are the first to feel the impact, but the consequences also affect the IT department. When a customer asks whether there was a temperature deviation during the container's stay at the terminal, "No alarm was triggered" is not an acceptable answer. The real question is: Can it be proven that nothing happened? Without continuous, complete data, this proof is difficult—sometimes impossible.

Systems for monitoring refrigerated container connections reach their limits here, as they were primarily designed for operational purposes – which connections are active, which containers require attention – rather than for analytical or evidentiary purposes (see also: Remote reefer monitoring system: How to integrate it?). The necessary resolution, retention policies, and data integrity controls are needed to clearly demonstrate that port regulations were correctly followed throughout the entire stay.

Trip Logs

The current values only show port personnel the status in this very moment, not what happened during the voyage so far. This information is provided by the trip log. It reveals whether all requirements have been met or whether the reefer already poses a hidden risk due to deviations.

There are several occasions to review the trip logs:

-

Upon arrival or unloading, assess whether the container was stable during sea transport.

-

After alarms or anomalies, determine whether a problem is new or part of a longer-term pattern.

-

Before and after power outages or transhipment operations, to verify the recovery process.

-

When responding to customer or shipping line inquiries, especially regarding quality concerns.

In keeping with the principle of data tracking continuity, terminals must be able to view the parameter history for the entire voyage. Modern reefer monitoring solutions offer the ability to download the trip log files and display them in specialised tools.

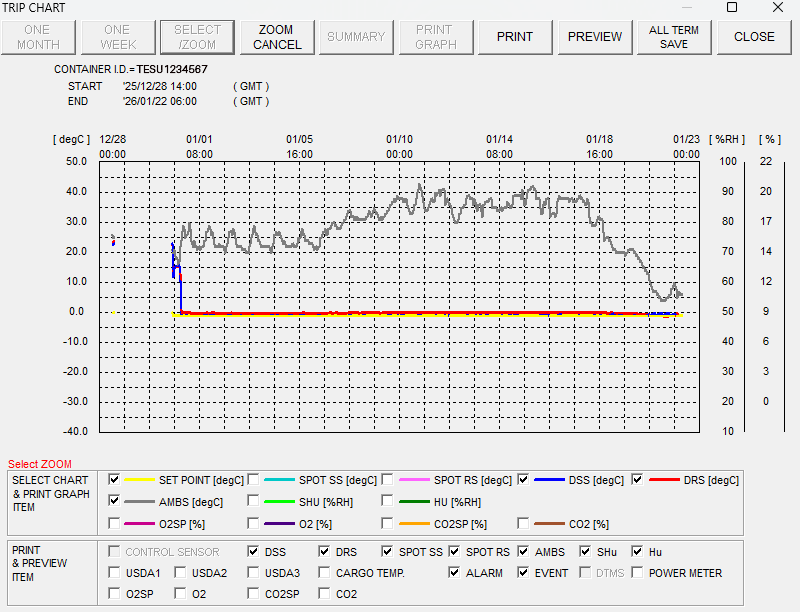

As shown in the image below, a range of voyage segment parameters preceding the port call can be easily understood at a glance.

[Illustration: What_is_reefer_monitoring_2.png]

The following chapter outlines scenarios in which the continuous collection of refrigerated container data is essential for success.

See also: Cold chain procedures and Reefer KPIs

Ripening, Stability, and Shelf Life as Data Problems

At first glance, maturation, pharmaceutical stability, and shelf life seem like completely different worlds. One concerns fresh produce, another strictly regulated pharmaceuticals, and the third subsequent commercial availability. What connects them is not the product itself, but rather the time spent under controlled conditions—and the data required to manage it.

In all three cases, problems often arise not from sudden failure, but from gradual, often unnoticed deviations. Without continuous, reliable data, these processes cannot be controlled—they can only be explained in retrospect. In the event of disputes, the terminal must prove that the container parameters complied with the specifications and maturation plans throughout the entire storage period. In such cases, monitoring data is the only neutral point of reference – provided it is complete, accurate, and timely.

Who Controls the Ripening Clock?

In theory, the answer seems simple. The ripening parameters are set by the goods owner or shipper, implemented by the refrigeration system, and continuously monitored. In practice, however, this optimally planned, time-critical process can be disrupted by delays that transform the ripening process from perfectly timed to economically compromised.

The ripening process can begin earlier than planned due to parameter changes or later due to, for example, undetected power outages. In all these cases, the physical process continues. Therefore, data continuity via distributed state management becomes crucial here as well: Vessel systems, terminal platforms, and truck drivers each only have a view of a portion of reality. If timestamps differ, or if events or parameter changes are not logged correctly, no one can say for sure when the ripening actually began—or whether it proceeded as planned.

Stability Budgets Raise the Bar for Data Integrity

The stability budget defines how much cumulative temperature stress a pharmaceutical product can tolerate before its quality, safety, or efficacy can no longer be guaranteed. Unlike simple threshold models, stability budgets are time-dependent and irreversible. Every hour spent at a specific temperature consumes a portion of the limited budget. Once exhausted, it cannot be replenished—no matter how perfect the conditions are afterwards.

This means that refrigerated container data also serves to quantify remaining product viability. This increases the demands on accuracy, completeness, and traceability. Missing data points are not only inconvenient gaps but also create uncertainty about how much of the stability budget was consumed during the terminal stay. This is where monitoring and regulation overlap. Pharmaceutical supply chains are subject to GDP, GMP, and increasingly stringent data integrity requirements. Timestamps must be reliable, data tamper-proof, and historical records accessible even months or years later. A data set that is acceptable for operational troubleshooting may be completely inadequate for a QA team or a regulatory authority.

Why Shelf Life Is Not a Fixed Attribute

Shelf life is calculated under assumed conditions. However, it does not decrease linearly: Small deviations in parameters do not always cause immediate damage, but gradually reduce future shelf life. A brief temperature increase may not trigger an alarm, but can accelerate biochemical processes that shorten the remaining shelf life by days. If these micro-deviations accumulate over a long transport route, the effect becomes significant – often without a single event being identifiable as the cause.

For terminals, monitoring data takes on a new strategic value. If the status data is sufficiently comprehensive and reliable, it can be transformed into decision-relevant information for downstream stakeholders. Importers can prioritise containers with reduced shelf life. Distribution centres can adjust routes. Retailers can tailor promotions to the actual remaining lifespan of the products. In all these cases, the terminal's data contributes to decisions that extend far beyond its physical boundaries.

Integrating Reefer Monitoring in the IT Landscape

In most terminals, the integration of refrigerated container monitoring is an organically grown system. Starting with paper records, the system may have evolved to manual recording on devices. However, automated monitoring systems were and often still are siloed solutions. Over time, expectations have changed. What was once a peripheral tool is now expected to provide data for operational processes, customer portals, analytics platforms, and compliance workflows. The result, in many cases, is an integration challenge for which IT was not designed, but which it now has to fully manage.

At its core, integration means allowing status data, timestamps, events, and alarms to flow into the Terminal Operations System (TOS) in near real-time, which in turn controls container movements, scheduling, and workflows. When a refrigerated container is connected or disconnected, or when an exception occurs, the TOS captures this directly with precise timestamps. This enables downstream processes—such as scheduling, invoicing, dispute resolution, and compliance reporting—to be based on a single source of data.

Architecturally, this integration typically uses APIs and secure data interfaces to synchronise data between the monitoring platform and the TOS. This makes the refrigerated container monitoring system part of the terminal's digital infrastructure, improving operational efficiency, data quality, and the ability to proactively respond to exceptions.

Ultimately, integration into the IT landscape—especially the TOS—transforms refrigerated container monitoring from a standalone visualisation tool into a central asset that enhances decision-making, reduces risk, and strengthens enterprise-wide accountability.

FAQ

Why Do Bananas and Ethylene Expose the Cost of Poor System Synchronisation?

Banana ripening is not a passive consequence of transport, but an actively controlled biological process. Harvested bananas are transported green, with respiration deliberately slowed by low temperatures and controlled atmospheres. Ripening only begins when this equilibrium is intentionally shifted, usually through the application of ethylene in combination with carefully controlled temperature and ventilation profiles.

What makes this process particularly sensitive is its irreversibility. Once ripening has begun, it cannot be stopped or reversed. The ethylene exposure initiates a cascade of biochemical reactions: starch is converted into sugar, cell walls soften, and color changes occur. If this sequence begins too early, the bananas can reach their ripeness before arrival. If it begins too late, they may not develop the desired quality for retail in time. In both cases, market value is lost.

Therefore, timing is crucial. The ripening process must be coordinated not only with the transport duration, but also with the unloading schedule, onward transport, and the planned market launch. A deviation of just a few hours can delay the entire ripening process, shorten the available sales window, or lead to increased waste.

Takeaway

The monitoring of refrigerated containers has evolved from a technical support function to a strategic data competency. For container terminals, this development is changing the expectations placed on IT: the crucial factor is the ability to provide uninterrupted, reliable, and traceable data throughout the container's time in the terminal.

If refrigerated container monitoring data is fragmented, poorly integrated, or incomplete, the terminal is vulnerable – not only operationally, but also commercially and legally. Conversely, if monitoring is fully integrated into the IT landscape, particularly the terminal operating system (TOS), it builds trust: with customers, regulatory authorities, and internal decision-makers. In this sense, refrigerated container monitoring is no longer just about protecting cargo. It's about maintaining the terminal's credibility in an environment where data reliably determines accountability.

Delve deeper into one of our core topics: Reefer monitoring

Glossary

Ripening in fruits is the physiological and biochemical process through which mature but unripe fruit develops edible quality—softer texture, sweeter taste, characteristic colour, and aroma. It involves starch breakdown into sugars, degradation of chlorophyll with exposure or synthesis of other pigments, and enzymatic modification of cell walls, leading to softening. In many species, the plant hormone ethylene triggers and coordinates these changes, especially in climacteric fruits like bananas, apples, and tomatoes, which can continue ripening after harvest. (3)

Ventilation circulates cold air evenly through the cargo load to maintain uniform temperature, remove heat from respiration (especially fruits/vegetables), control humidity, and prevent CO₂ buildup or hot spots. Air delivery occurs through a T-shaped floor with vents, flowing upward through gaps in pallets/stacks and returning via ceiling/top vents to the evaporator for recooling. Adjustable settings (e.g., 20–100 m³/h) match cargo needs—vented for respiring produce, closed for frozen goods—to optimise quality and shelf life during sea/land transit. (4)

References

(1) https://www.foodengineeringmag.com/articles/101206-food-waste-mitigation-via-transportation

(3) Wills, R.B.H., McGlasson, W.B., Graham, D., Joyce, D. (2007). Postharvest: An Introduction to the Physiology & Handling of Fruit, Vegetables & Ornamentals. CABI.

(4) Thompson, James F.; Mitchell, Frank G. (2002). Cooling Horticultural Commodities. In: Postharvest Technology of Horticultural Crops. University of California DANR.

Note: This article was partly created with the assistance of artificial intelligence to support drafting.

Author

Conny Stickler, Marketing Manager Logistics

Constance Stickler holds a master's degree in political science, German language and history. She spent most of her professional career as a project and marketing manager in different industries. Her passion is usability, and she's captivated by the potential of today's digital tools. They seem to unlock endless possibilities, each one more intriguing than the last. Constance writes about automation, sustainability and safety in maritime logistics.